Lesson 01: Broken

*Wear gloves during the entire process, as urushi can cause severe rash.

*We assume no responsibility for any health hazards.

1. Chamfering of the broken parts

First, lightly scrape the corners of the broken pieces with a diamond file.

hamfering creates a groove in the seams, which allows the urushi to settle on the seams.

Be careful not to use too much force, as it will chip the ceramics.

A groove about 0.5 mm wide is sufficient.

2. Making "Mugi-urishi"

Once you have finished beveling the pieces, glue the pieces together.

For gluing, a mixture of cake flour, water, and raw urushi called "Mugi-Urushi" is used.

- Ingredients for Mugi-Urushi

- Cake flour: 1 grated spoonful

- Water: 1 grated spoonful (a little less)

- Raw urushi: 2 grated spoonful

- ※With 0.1ml measuring spoon

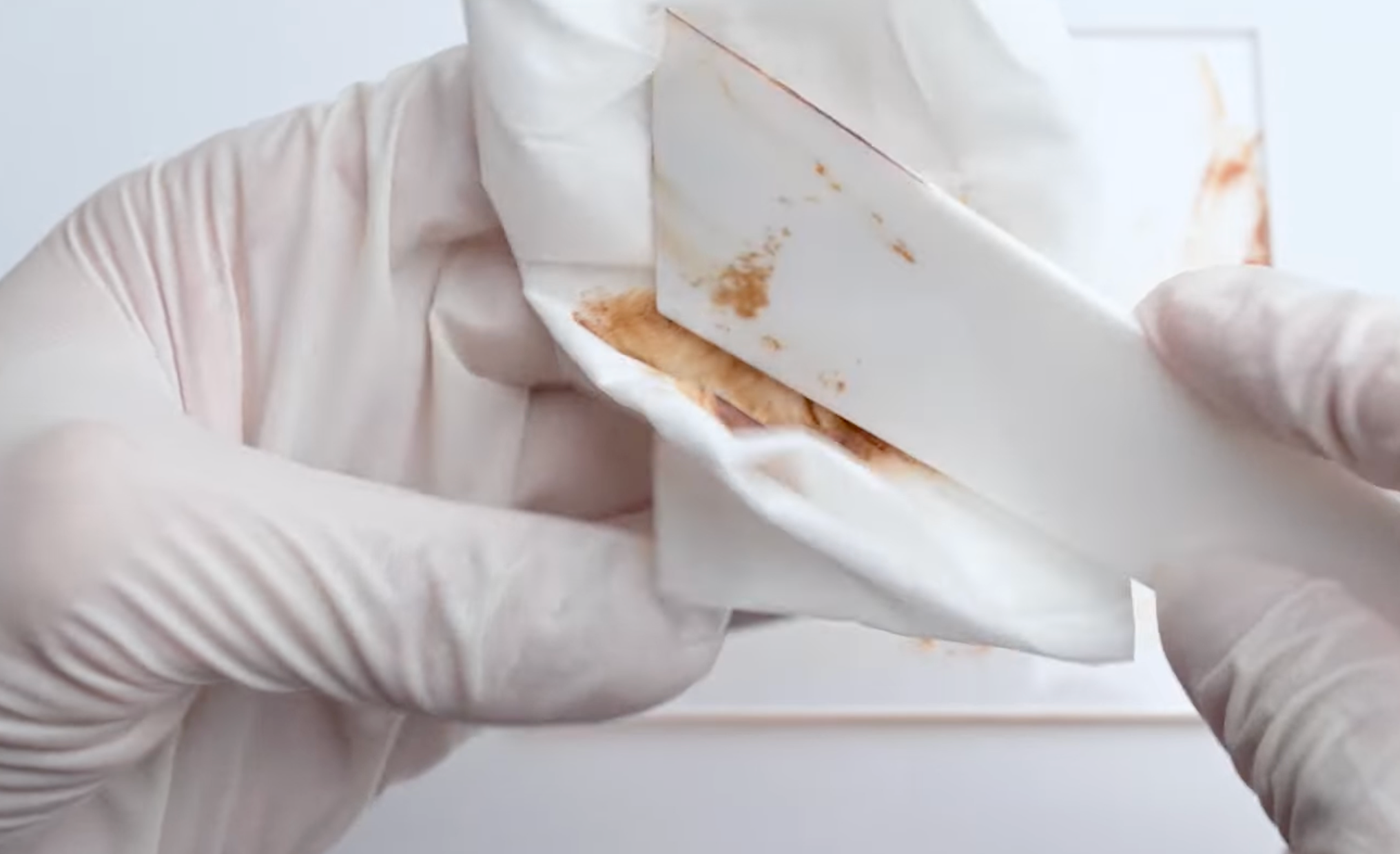

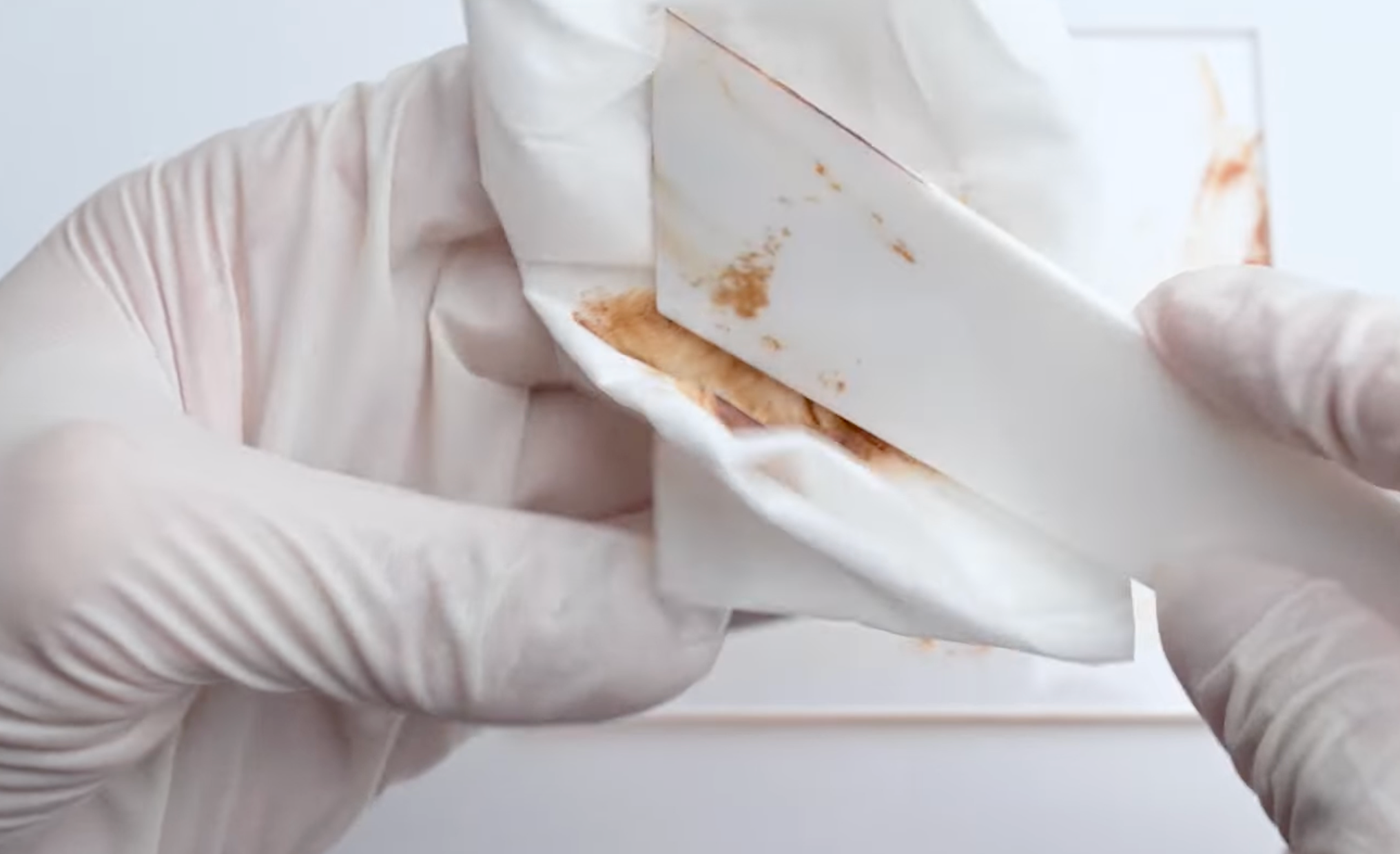

First, mix cake flour and water on an acrylic board and knead until the mixture resembles bread dough.

If it does not resemble bread dough and is too watery, remake it again.

Then add raw urushi and knead well with a spatula.

When the surface becomes smooth and stretchy, "Mugi-Urushi" is completed.

If it does not stretch well enough, add raw urushi little by little to adjust it.

3. Prepare masking tapes

In advance, prepare shredded masking tape for use when gluing.

Depending on the size of the ceramics and the number of fragments, prepare about 10 pieces at a time.

(It is quite difficult to shred the tape while gluing)

4. Glue pieces together

It is time to glue the pieces together. Apply a thin layer of mugi-urushi to the cross section of the fragments.

*For ceramics with thin glaze or those which urushi is likely to bleed through, use masking tape to protect the area around the joints in advance.

After applying mugi-urushi to the cross sections of all the pieces, glue the pieces together.

The important thing is to glue and crimp them together precisely so that there is no misalignment. Be careful not to create gaps or bumps.

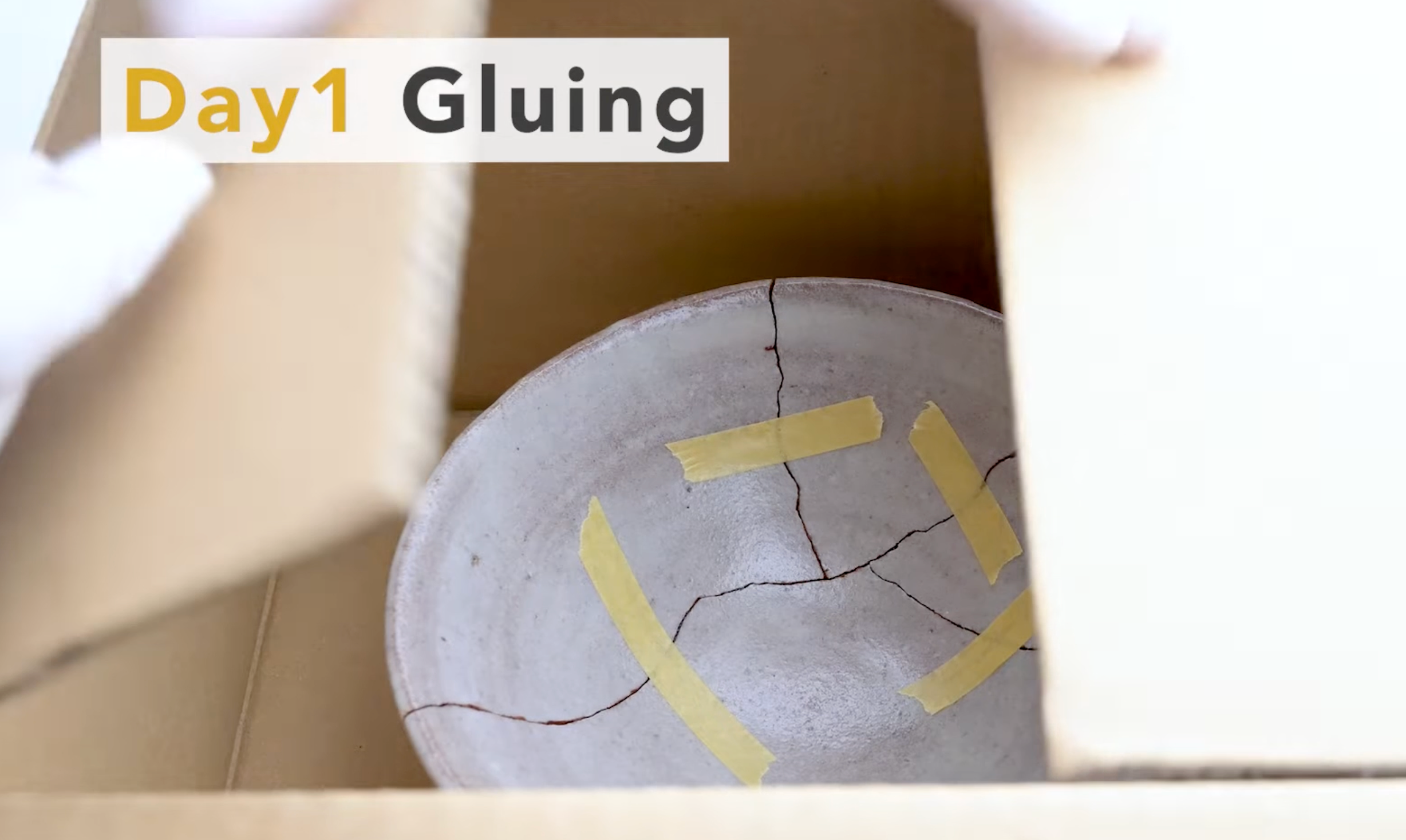

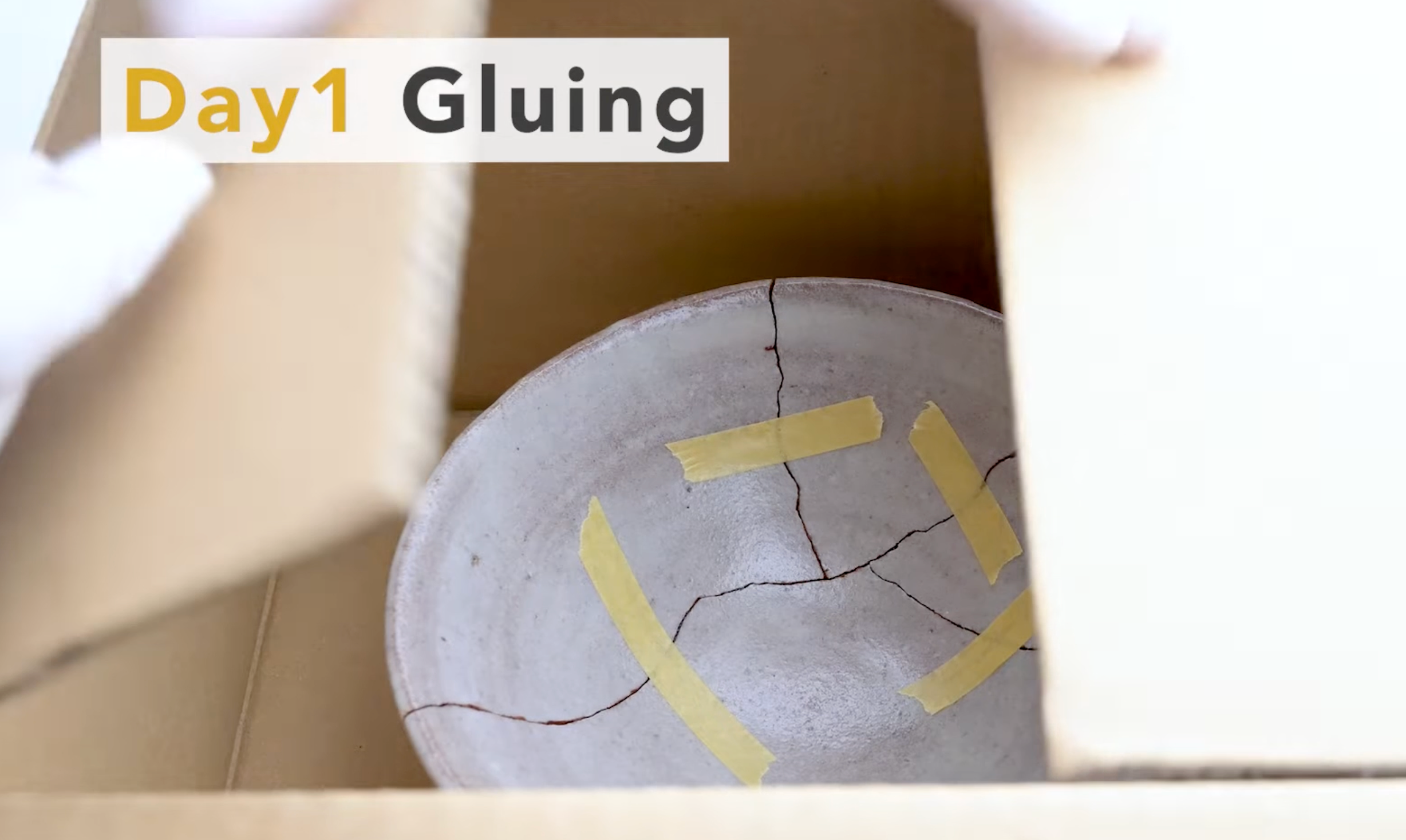

5. Fasten with masking tape

As soon as you have glued one of the pieces, apply masking tape to secure it.

This will prevent the pieces from shifting from each other until they are completely glued.

Once secured, glue the next piece of fragments.

6. Wait about 1 week for the mugi-urushi to harden

At this point, the gluing process has been completed. Wait about a week for the mugi-urushi to harden firmly.

Mugi urushi does not need much humidity to harden, but it may not harden sufficiently in dry areas, for example.

To be safe, keep it in a place with a humidity of around 70% and a temperature of around 25 degrees Celsius.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

How to wash tools

Wipe off any tools with urushi using a tissue moistened with ethanol.

All tools except for the brush can be wiped off with ethanol.

*Wear gloves during the entire process, as urushi can cause severe rash.

*We assume no responsibility for any health hazards.

1. Chamfering of the broken parts

First, lightly scrape the corners of the broken pieces with a diamond file.

hamfering creates a groove in the seams, which allows the urushi to settle on the seams.

Be careful not to use too much force, as it will chip the ceramics.

A groove about 0.5 mm wide is sufficient.

2. Making "Mugi-urishi"

Once you have finished beveling the pieces, glue the pieces together.

For gluing, a mixture of cake flour, water, and raw urushi called "Mugi-Urushi" is used.

- Ingredients for Mugi-Urushi

- Cake flour: 1 grated spoonful

- Water: 1 grated spoonful (a little less)

- Raw urushi: 2 grated spoonful

- ※With 0.1ml measuring spoon

First, mix cake flour and water on an acrylic board and knead until the mixture resembles bread dough.

If it does not resemble bread dough and is too watery, remake it again.

Then add raw urushi and knead well with a spatula.

When the surface becomes smooth and stretchy, "Mugi-Urushi" is completed.

If it does not stretch well enough, add raw urushi little by little to adjust it.

3. Prepare masking tapes

In advance, prepare shredded masking tape for use when gluing.

Depending on the size of the ceramics and the number of fragments, prepare about 10 pieces at a time.

(It is quite difficult to shred the tape while gluing)

4. Glue pieces together

It is time to glue the pieces together. Apply a thin layer of mugi-urushi to the cross section of the fragments.

*For ceramics with thin glaze or those which urushi is likely to bleed through, use masking tape to protect the area around the joints in advance.

After applying mugi-urushi to the cross sections of all the pieces, glue the pieces together.

The important thing is to glue and crimp them together precisely so that there is no misalignment. Be careful not to create gaps or bumps.

5. Fasten with masking tape

As soon as you have glued one of the pieces, apply masking tape to secure it.

This will prevent the pieces from shifting from each other until they are completely glued.

Once secured, glue the next piece of fragments.

6. Wait about 1 week for the mugi-urushi to harden

At this point, the gluing process has been completed. Wait about a week for the mugi-urushi to harden firmly.

Mugi urushi does not need much humidity to harden, but it may not harden sufficiently in dry areas, for example.

To be safe, keep it in a place with a humidity of around 70% and a temperature of around 25 degrees Celsius.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

How to wash tools

Wipe off any tools with urushi using a tissue moistened with ethanol.

All tools except for the brush can be wiped off with ethanol.

1. Scrape off excess Mugi-urushi

Once the gluing is firmly completed, wipe off any dirt on the surface of the ceramics with an ethanol-soaked tissue.

If hard mugi urushi still protrudes from the surface, scrape it off with a cutter.

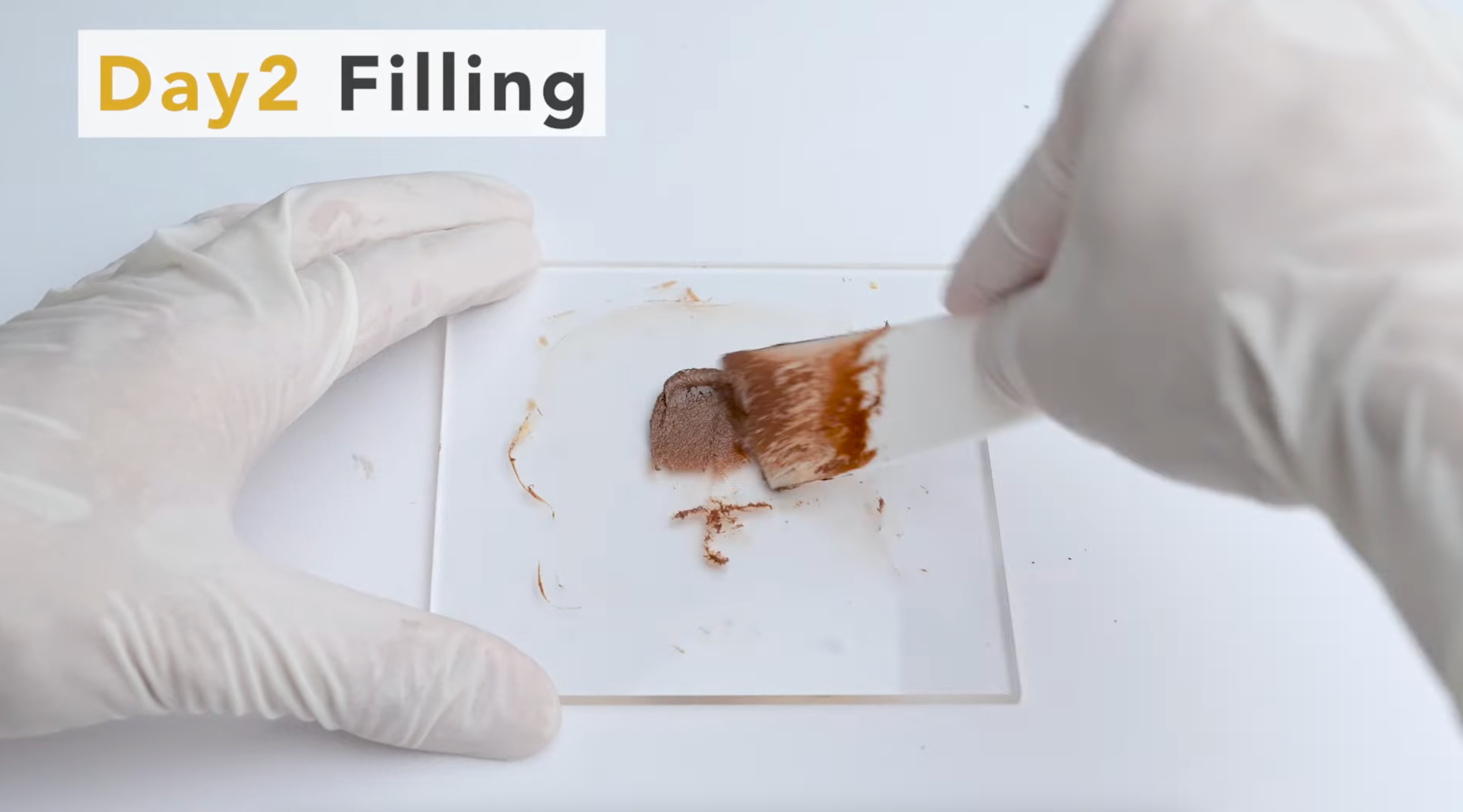

2. Making "Kokuso-urushi"

Once excess mugi-urushi is removed, we will use "Kokuso-urushi" to fill the chipped area.

- Ingredients for Kokuso-Urushi

- Cake flour: 1 grated spoonful

- Water: 1 grated spoonful

- Raw urushi: 2 grated spoonful

- Wood powder: 2 grated spoonful

- ※With 0.1ml measuring spoon

First, mix cake flour and water on an acrylic board and knead until the mixture resembles bread dough. If it does not resemble bread dough and is too watery, remake it again.

Then add raw urushi and knead well with a spatula.

When the surface becomes smooth and stretchy, add wood powder and knead well.

When the ingredients are well mixed, "Kokuso-urushi" is ready.

3. Apply kokuso-urushi to the chipped area

Use Kokuso urushi to fill in the missing parts.

Thin glazed ceramics should have masking tape around them beforehand to prevent staining.

When applying kokuso urushi, keep the thickness to about 2mm at a time.

This is because if it is applied too thickly, the core may not harden.

For chips deeper than 2 mm, repeat this step several times.

If it is difficult to shape with a spatula, you can use your fingers.

Since it is sticky, it is easier to use plastic wrap.

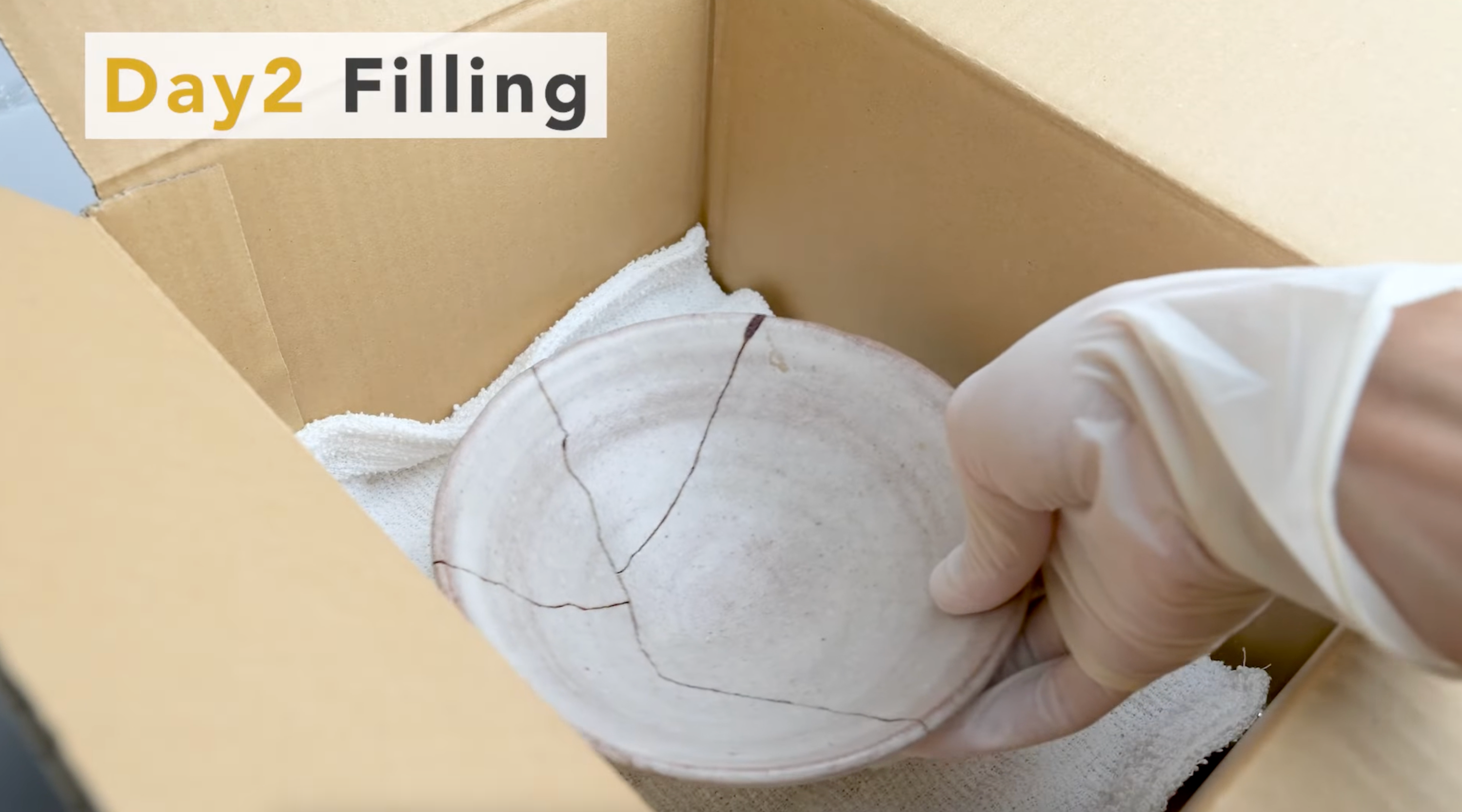

4. Wait about a week to harden

Wait a week for the kokuso-urushi to harden.

The kokuso-urushi does not need much humidity to harden, but it may not harden sufficiently in dry areas, for example.

To be safe, keep it in a place with a humidity of around 70% and a temperature of around 25 degrees Celsius.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

1. Scrape off excess Mugi-urushi

Once the gluing is firmly completed, wipe off any dirt on the surface of the ceramics with an ethanol-soaked tissue.

If hard mugi urushi still protrudes from the surface, scrape it off with a cutter.

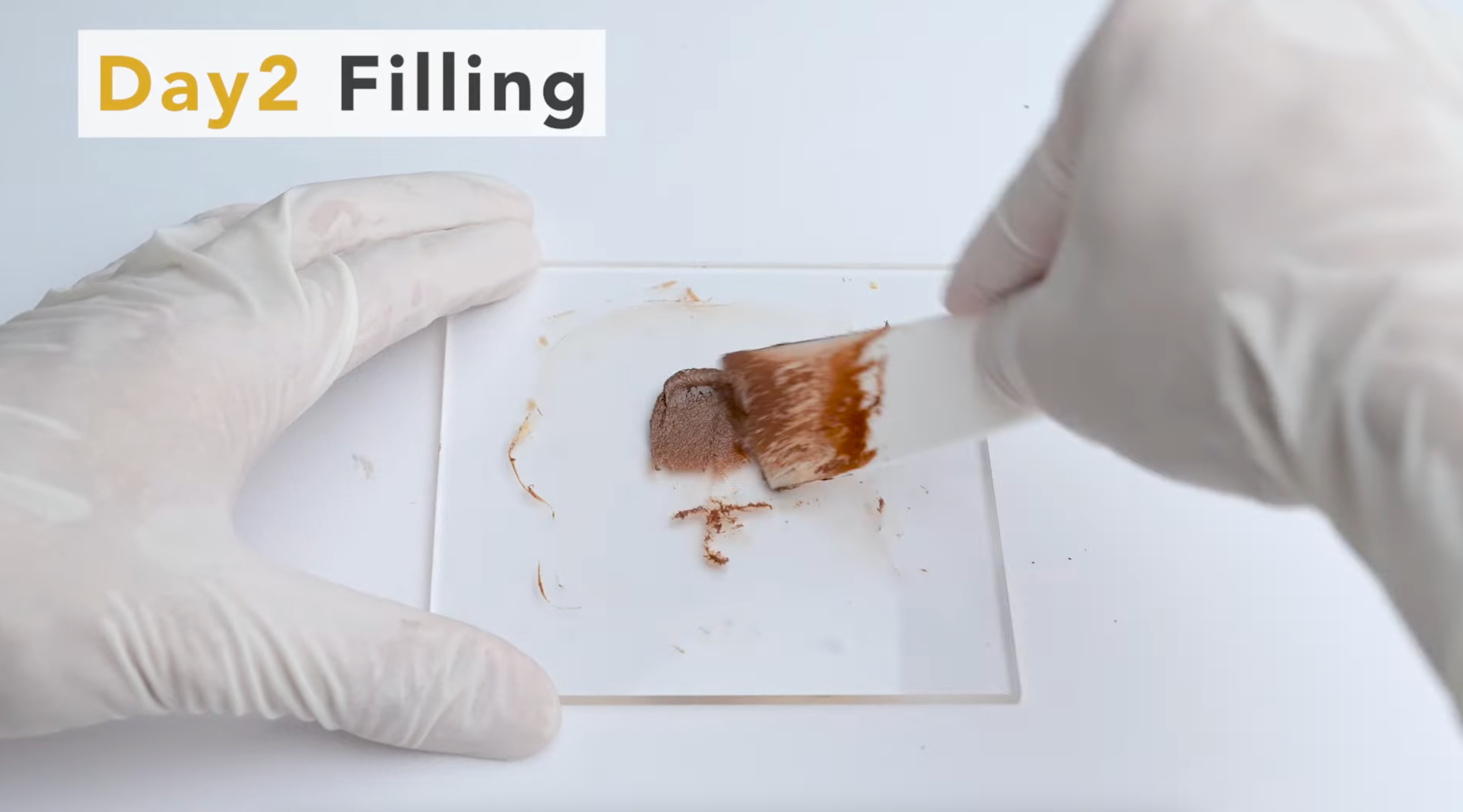

2. Making "Kokuso-urushi"

Once excess mugi-urushi is removed, we will use "Kokuso-urushi" to fill the chipped area.

- Ingredients for Kokuso-Urushi

- Cake flour: 1 grated spoonful

- Water: 1 grated spoonful

- Raw urushi: 2 grated spoonful

- Wood powder: 2 grated spoonful

- ※With 0.1ml measuring spoon

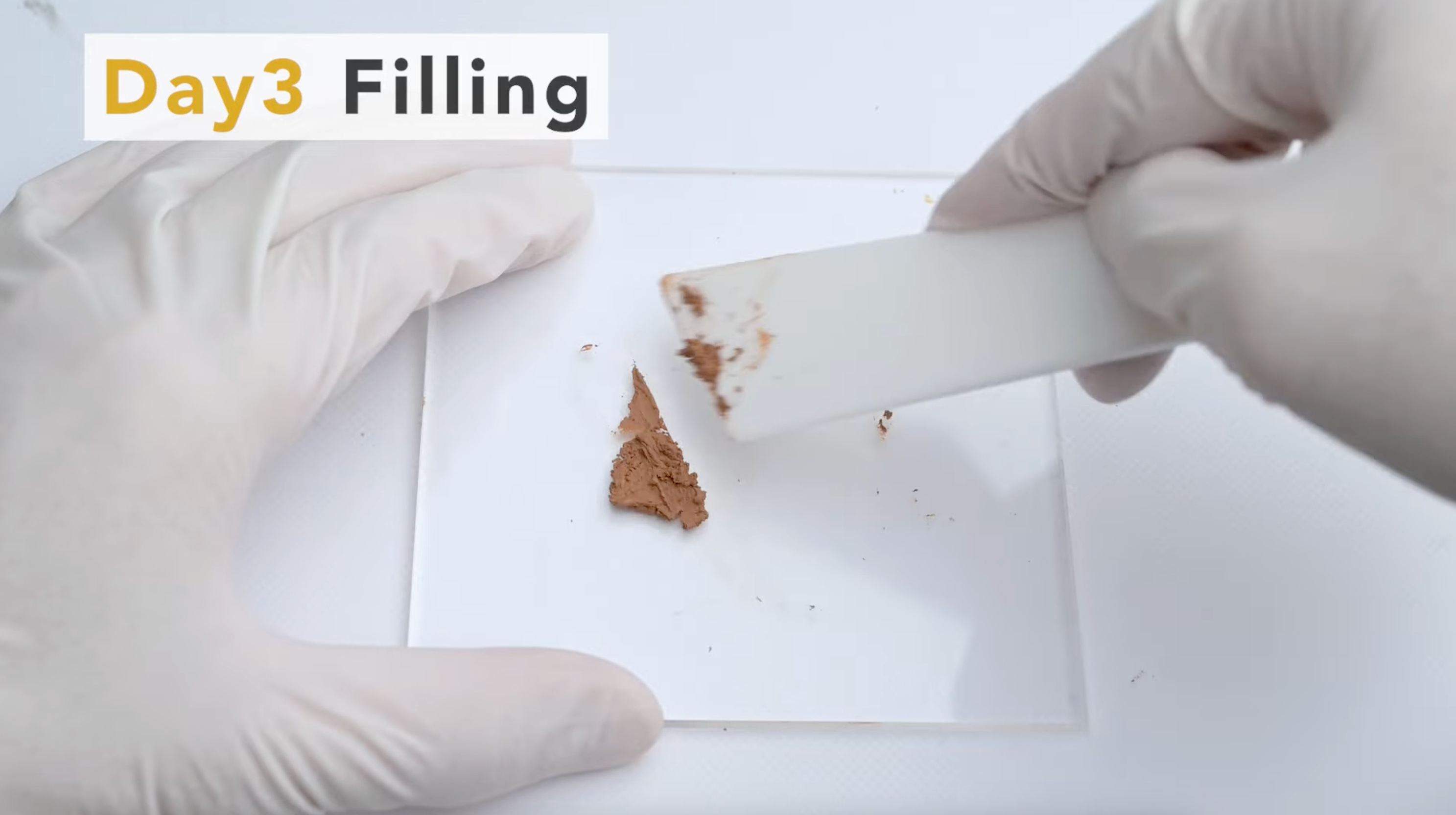

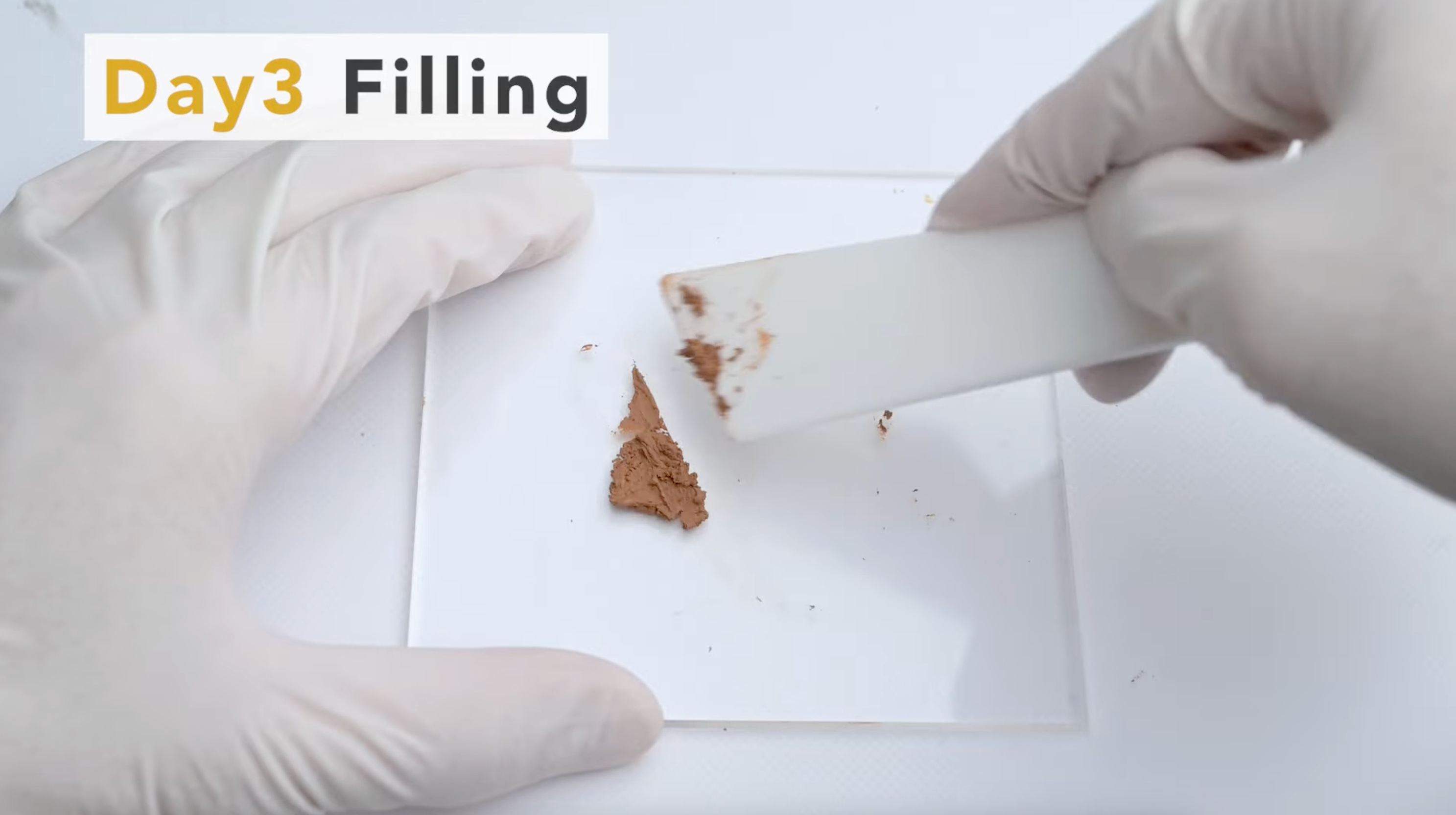

First, mix cake flour and water on an acrylic board and knead until the mixture resembles bread dough. If it does not resemble bread dough and is too watery, remake it again.

Then add raw urushi and knead well with a spatula.

When the surface becomes smooth and stretchy, add wood powder and knead well.

When the ingredients are well mixed, "Kokuso-urushi" is ready.

3. Apply kokuso-urushi to the chipped area

Use Kokuso urushi to fill in the missing parts.

Thin glazed ceramics should have masking tape around them beforehand to prevent staining.

When applying kokuso urushi, keep the thickness to about 2mm at a time.

This is because if it is applied too thickly, the core may not harden.

For chips deeper than 2 mm, repeat this step several times.

If it is difficult to shape with a spatula, you can use your fingers.

Since it is sticky, it is easier to use plastic wrap.

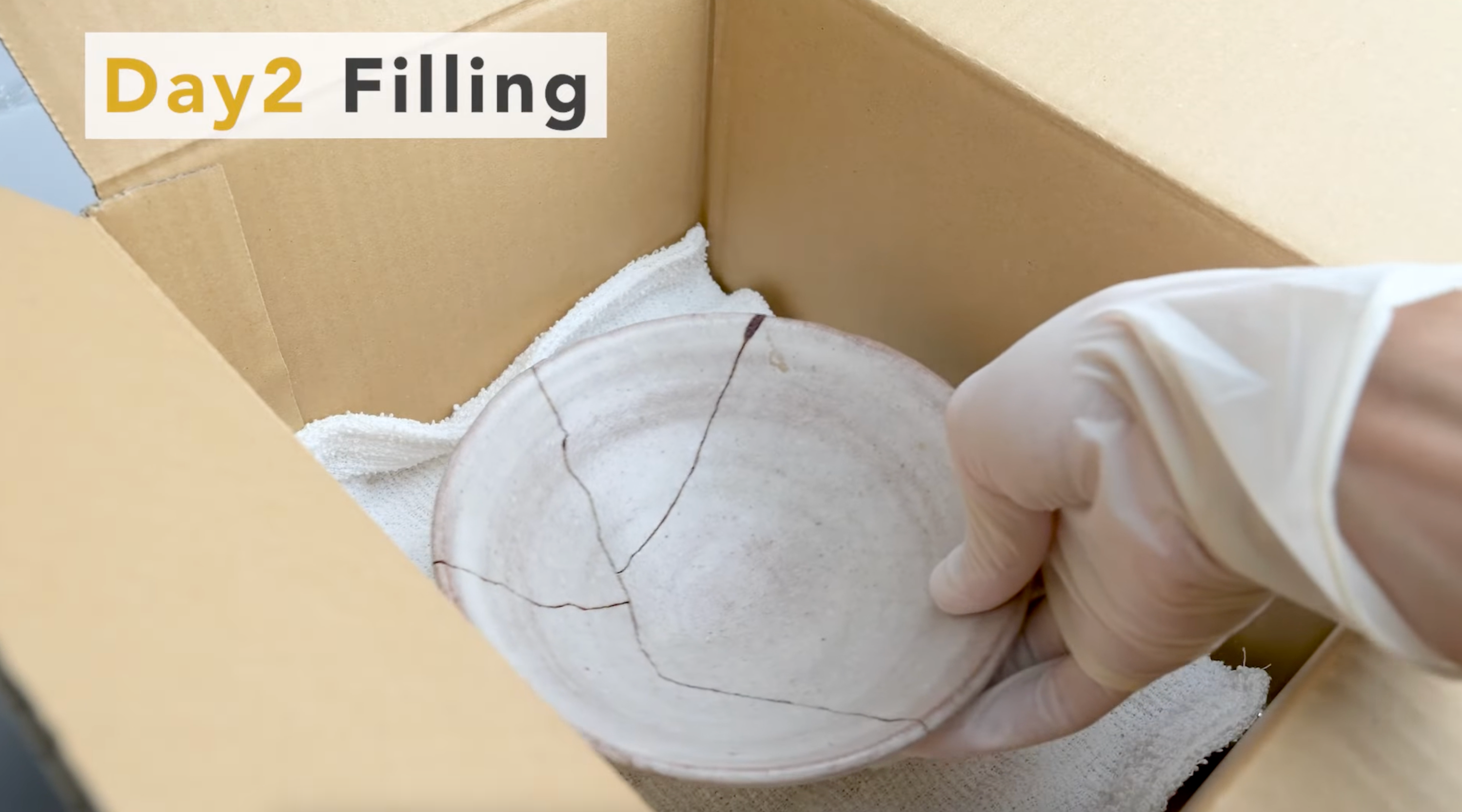

4. Wait about a week to harden

Wait a week for the kokuso-urushi to harden.

The kokuso-urushi does not need much humidity to harden, but it may not harden sufficiently in dry areas, for example.

To be safe, keep it in a place with a humidity of around 70% and a temperature of around 25 degrees Celsius.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

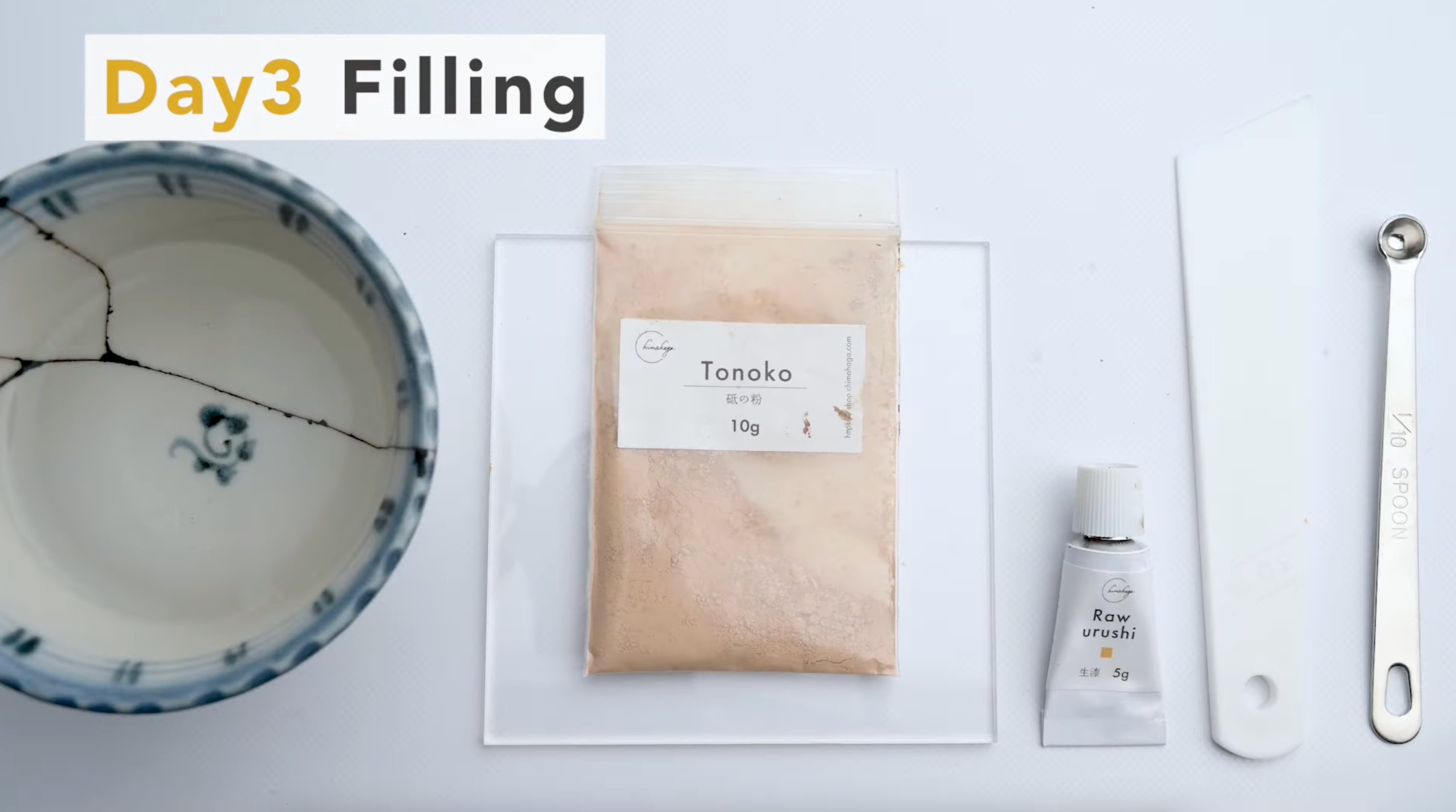

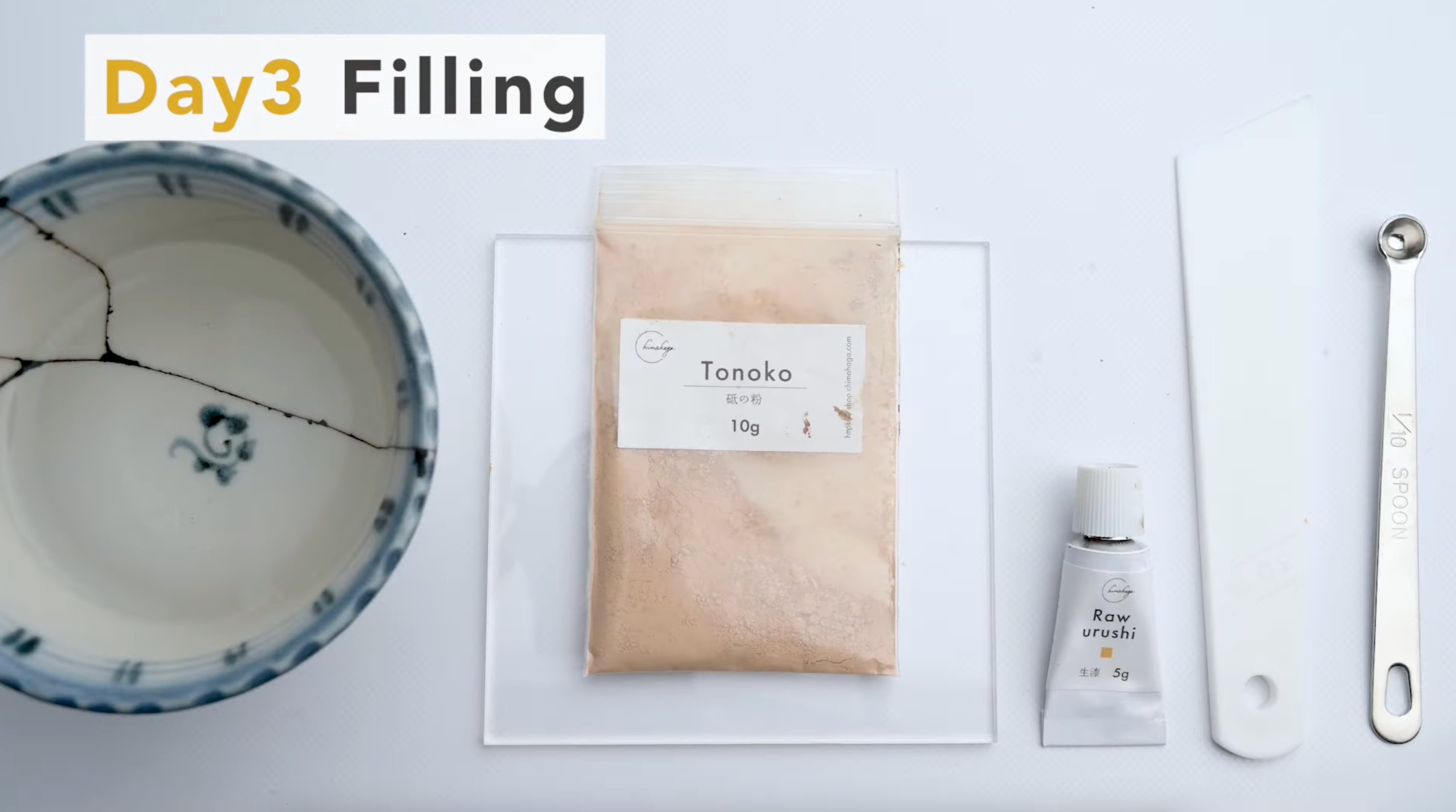

1. Scrape off excess Kokuso-urushi

Once the kokuso-urushi is firmly hardened, scrape it off with a cutter.

Thin stains should be wiped up with ethanol.

Shave it as much as possible to get as close to the original ceramics shape as possible.

The lacks will be filled in the next step, so now let's shave off the excess and shape it.

2. Making "Sabi-urushi"

Once excess kokuso-urushi is removed, we will use "Sabi-urushi" to fill the seams.

- Ingredients for Sabi-Urushi

- Tonoko: 2 grated spoonful

- Water: 1 grated spoonful

- Raw urushi: 1 grated spoonful

- ※With 0.1ml measuring spoon

First, take Tonoko on an acrylic plate, add water and mix them.

Then, add raw urushi and knead with a spatula.

The sabi-urushi dries quickly, so make it as small as possible and place the spatula on top to keep it out of the air.

3. Apply sabi-urushi to the seams

Apply sabi-urushi to the grooves at the seams.

※Use masking tape to protect unglazed pottery from stains.

The purpose of this step is to flatten the seams of the ceramics.

So, apply it so that no grooves are left.

4. Wait a few days to harden

Wait a few days for the sabi-urushi to harden.

The sabi-urushi does not need much humidity to harden, but it may not harden sufficiently in dry areas, for example.

To be safe, keep it in a place with a humidity of around 70% and a temperature of around 25 degrees Celsius.

- Note

- If you try to fill large chips with sabi-urushi, only the surface of the sabi-urushi might dry, leaving the inside dull. If the groove is more than 1mm deep, use "Kokuso-urushi" used for chipped repair.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

1. Scrape off excess Kokuso-urushi

Once the kokuso-urushi is firmly hardened, scrape it off with a cutter.

Thin stains should be wiped up with ethanol.

Shave it as much as possible to get as close to the original ceramics shape as possible.

The lacks will be filled in the next step, so now let's shave off the excess and shape it.

2. Making "Sabi-urushi"

Once excess kokuso-urushi is removed, we will use "Sabi-urushi" to fill the seams.

- Ingredients for Sabi-Urushi

- Tonoko: 2 grated spoonful

- Water: 1 grated spoonful

- Raw urushi: 1 grated spoonful

- ※With 0.1ml measuring spoon

First, take Tonoko on an acrylic plate, add water and mix them.

Then, add raw urushi and knead with a spatula.

The sabi-urushi dries quickly, so make it as small as possible and place the spatula on top to keep it out of the air.

3. Apply sabi-urushi to the seams

Apply sabi-urushi to the grooves at the seams.

※Use masking tape to protect unglazed pottery from stains.

The purpose of this step is to flatten the seams of the ceramics.

So, apply it so that no grooves are left.

4. Wait a few days to harden

Wait a few days for the sabi-urushi to harden.

The sabi-urushi does not need much humidity to harden, but it may not harden sufficiently in dry areas, for example.

To be safe, keep it in a place with a humidity of around 70% and a temperature of around 25 degrees Celsius.

- Note

- If you try to fill large chips with sabi-urushi, only the surface of the sabi-urushi might dry, leaving the inside dull. If the groove is more than 1mm deep, use "Kokuso-urushi" used for chipped repair.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

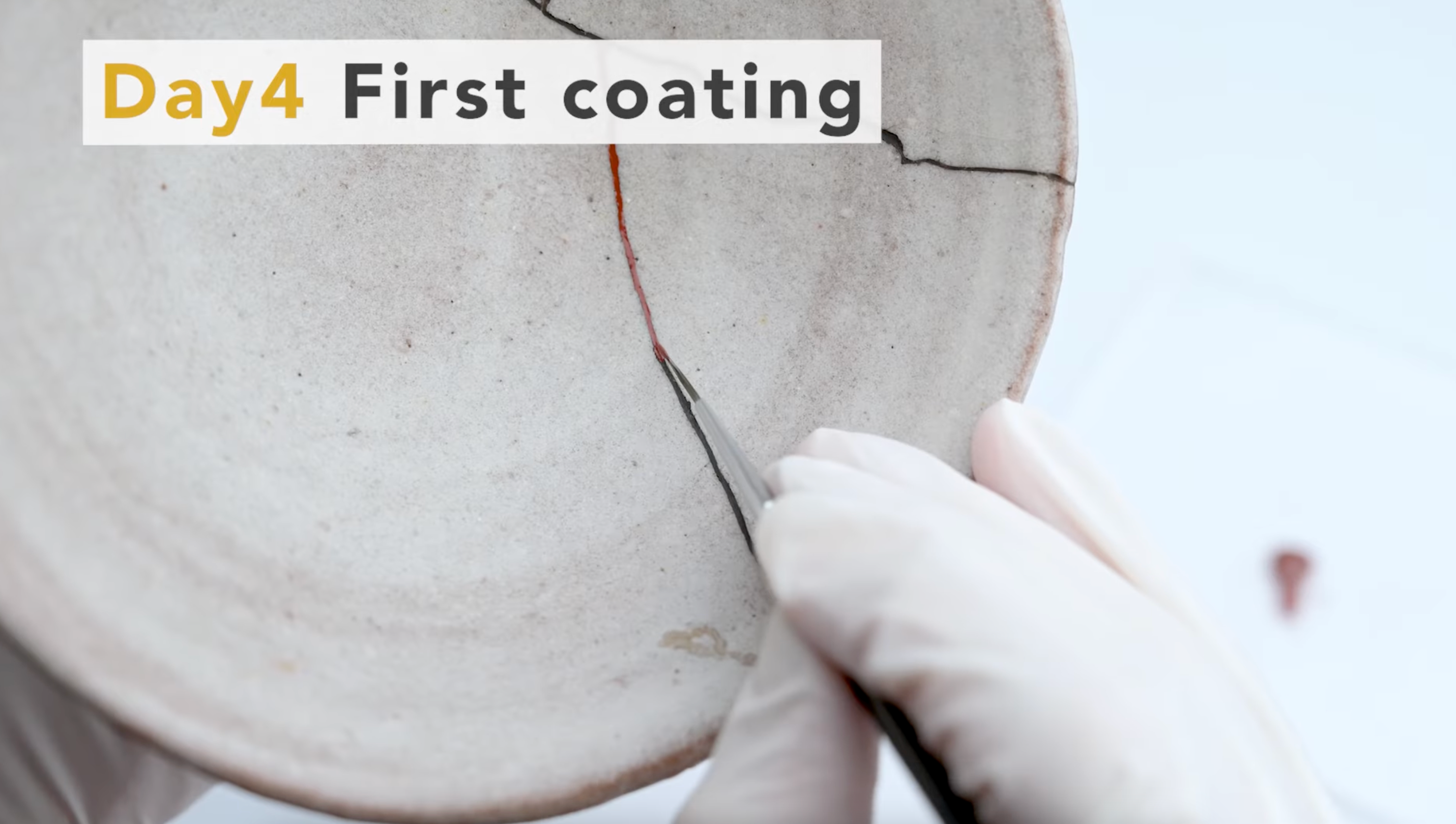

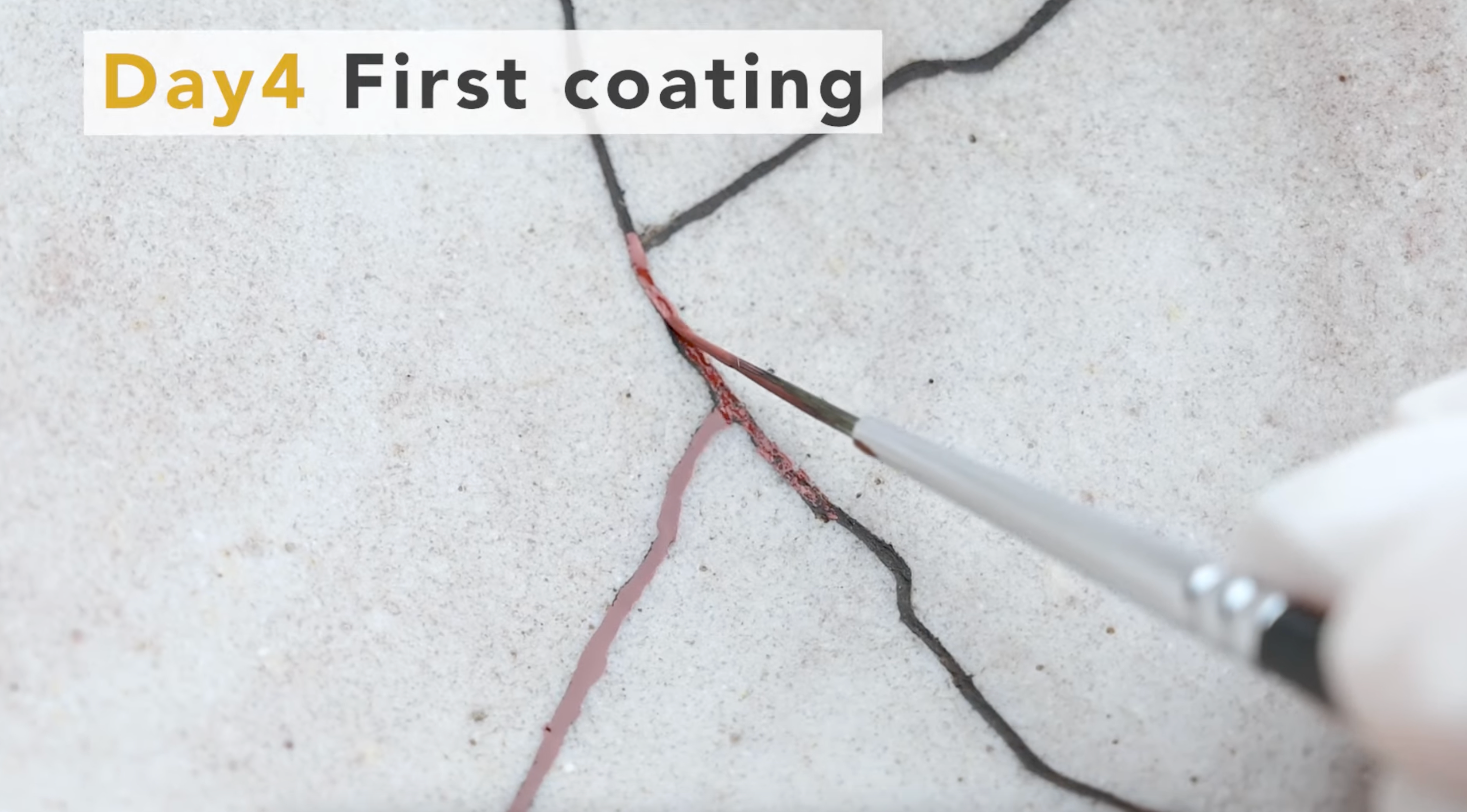

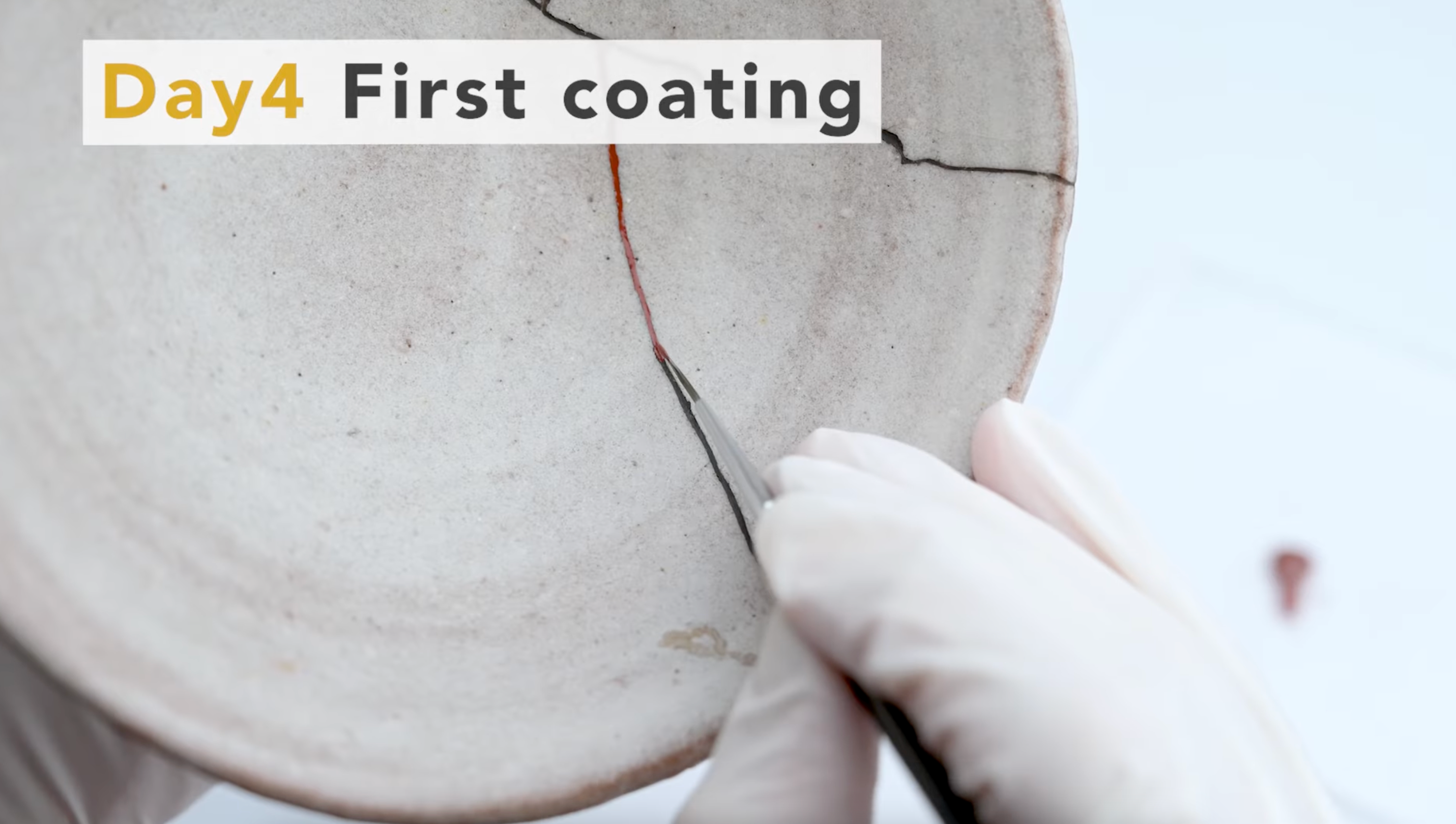

1. Scrape off the sabi-urushi

After the sabi-urushi has hardened, scrape off it on the overhangs with a cutter to make the seams flat and even.

If the surface is large and difficult to smooth with a cutter, use a sandpaper to smooth the surface as much as possible.

Wipe off any dirt on the surface of the ceramics with an ethanol-soaked tissue as appropriate.

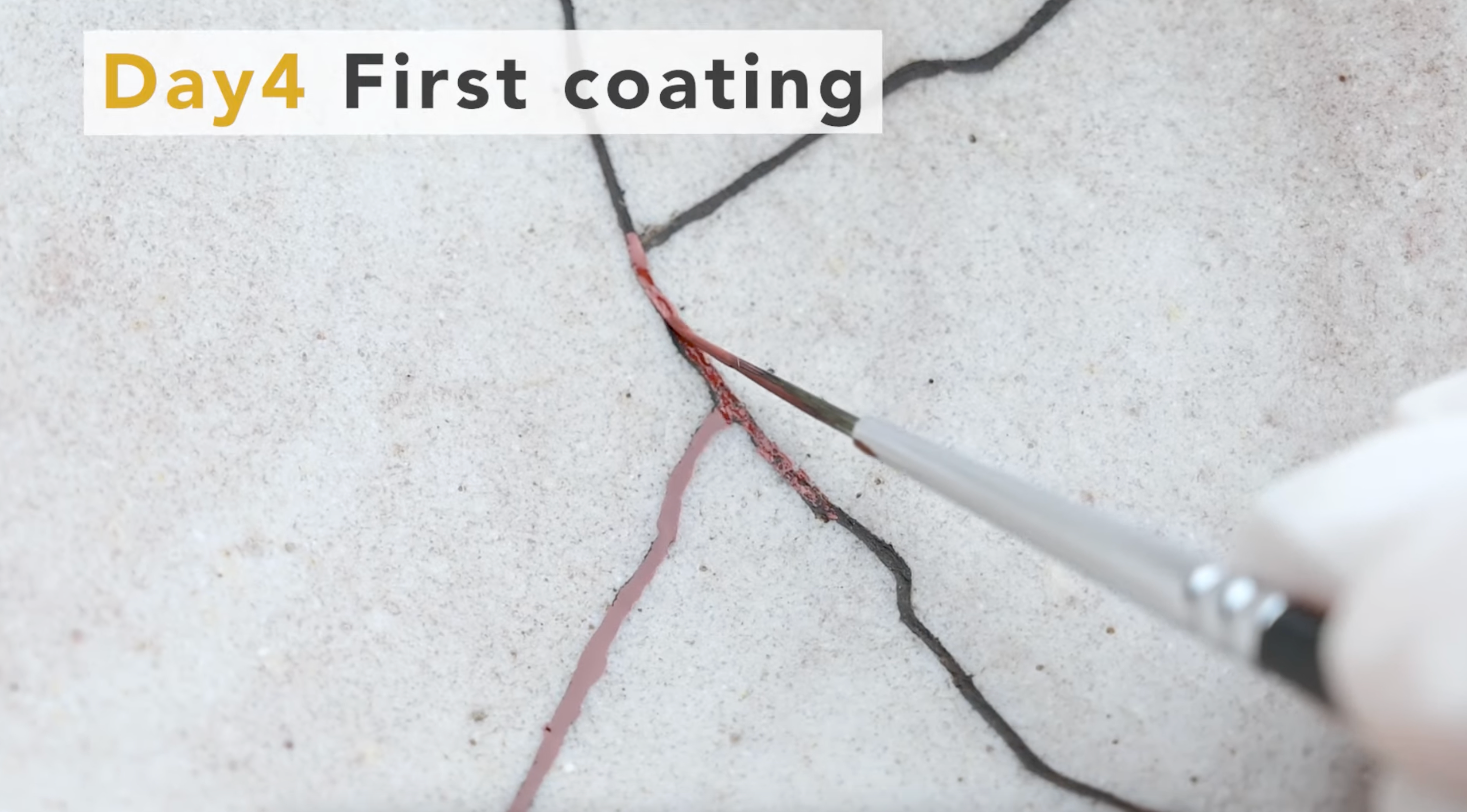

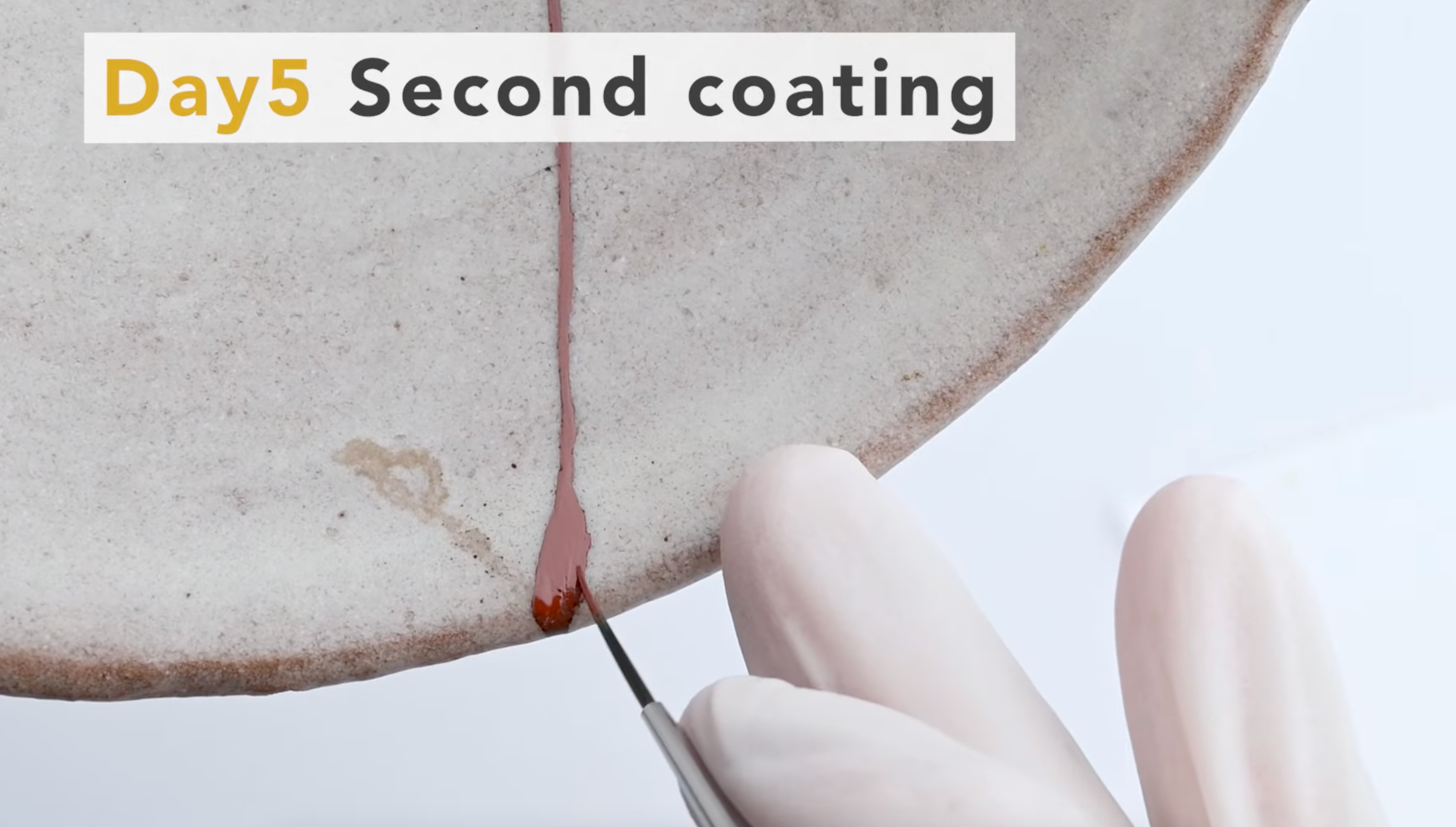

2. Coating the seams with "Bengara urushi"

Once the seams are flatten, coat the seams with "Bengara urushi".

Wipe the brush tip thoroughly with ethanol first before use.

It is recommended to apply the inside first because if you apply the outside first, you may touch the seam when applying the inside.

The purpose of this process is not to simply coat the seams, but to fill in the small dents by pouring bengara urushi into the seams to further flatten the surface.

Therefore, if the surface is rough like this, the coating is not sufficient.

Work as if you were "filling in the gaps with urushi" rather than "applying urushi".

Apply so that the surface is this smooth.

3. Wait few days to harden

When you have finished coating, leave it in the humid room and wait for a few days.

Also, keep the temperature around 25°C and the humidity around 70% because it will not harden if the temperature and humidity is too low.

On the other hand, too high a humidity of 80% or more is not good, as it may cause wrinkles when the urushi hardens.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

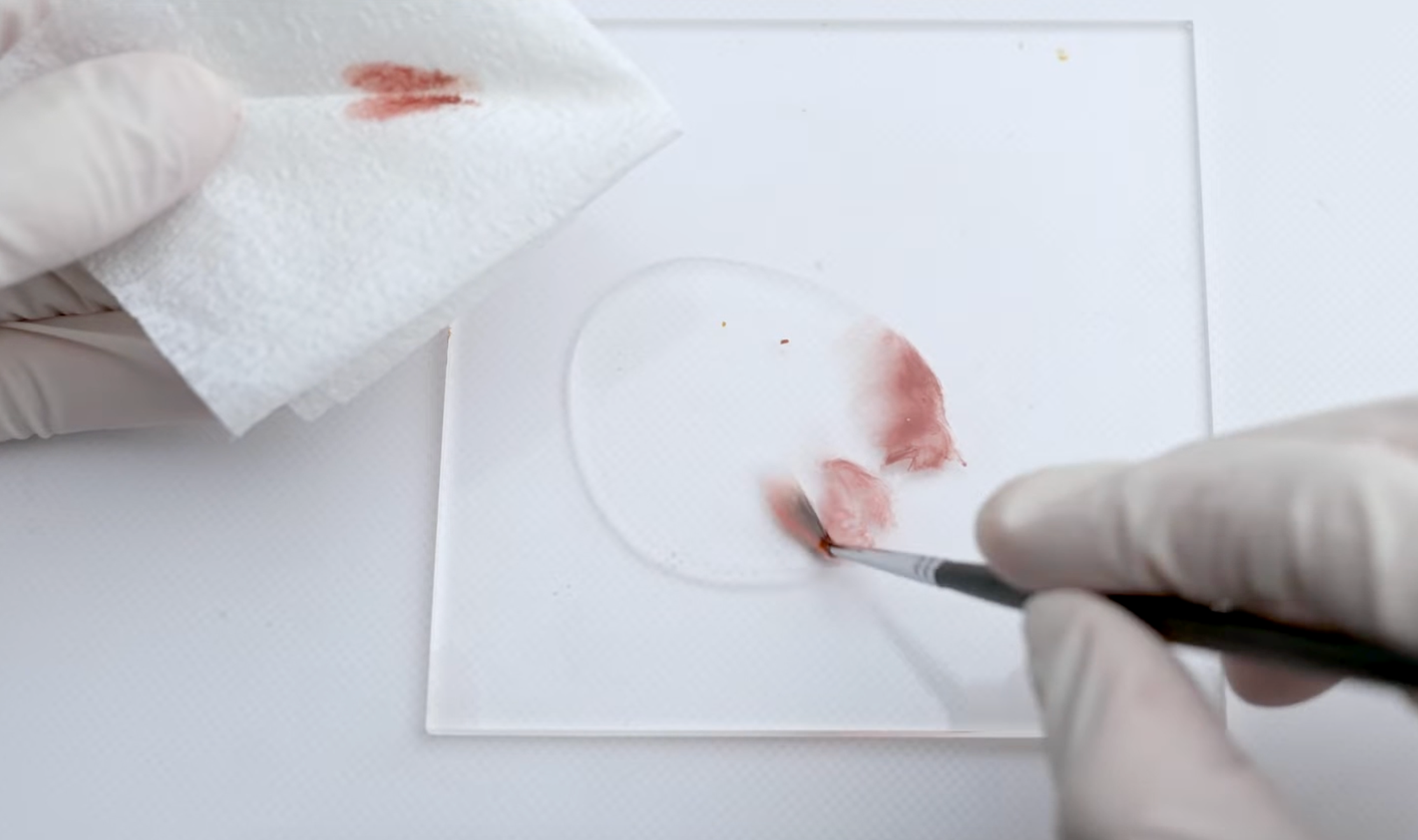

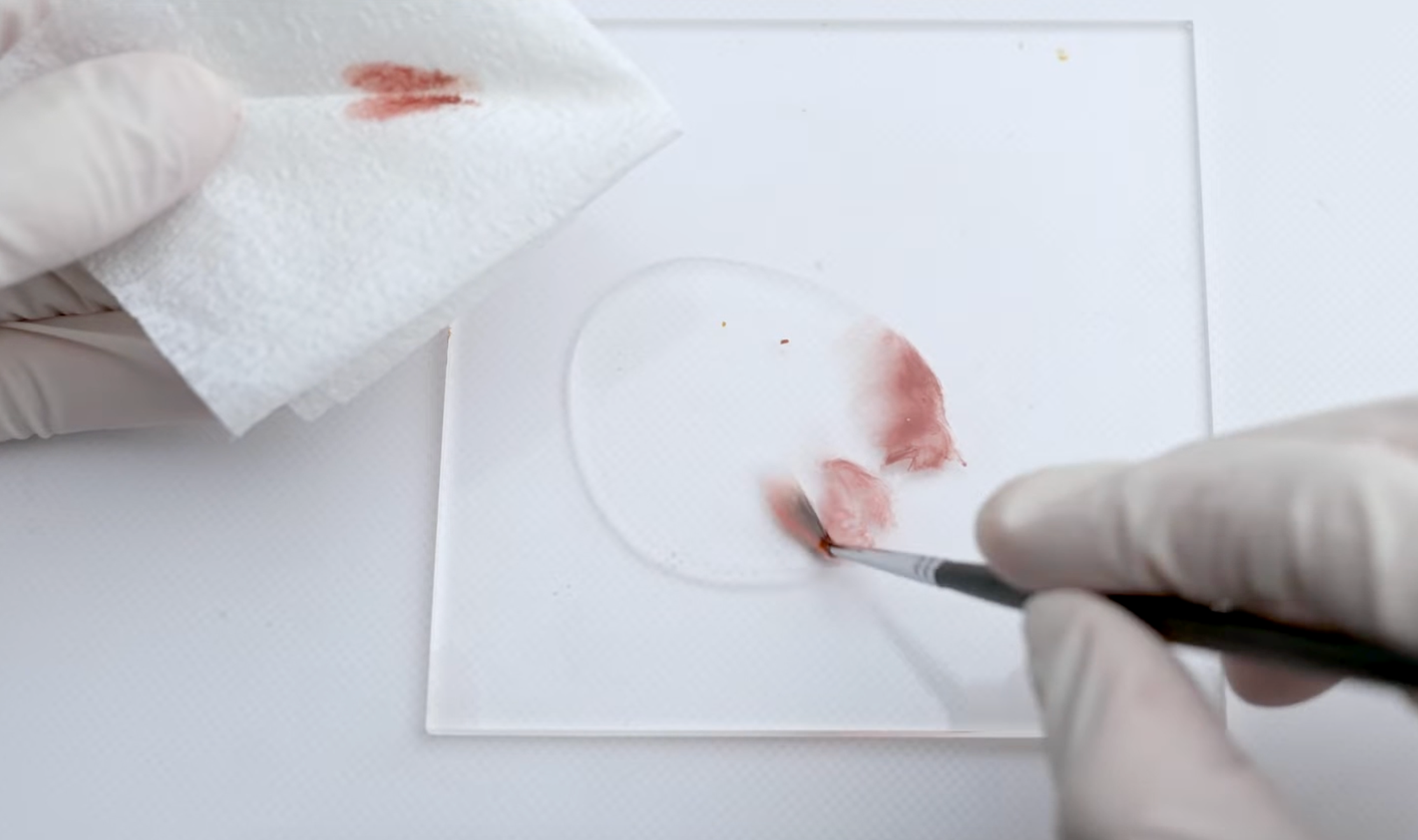

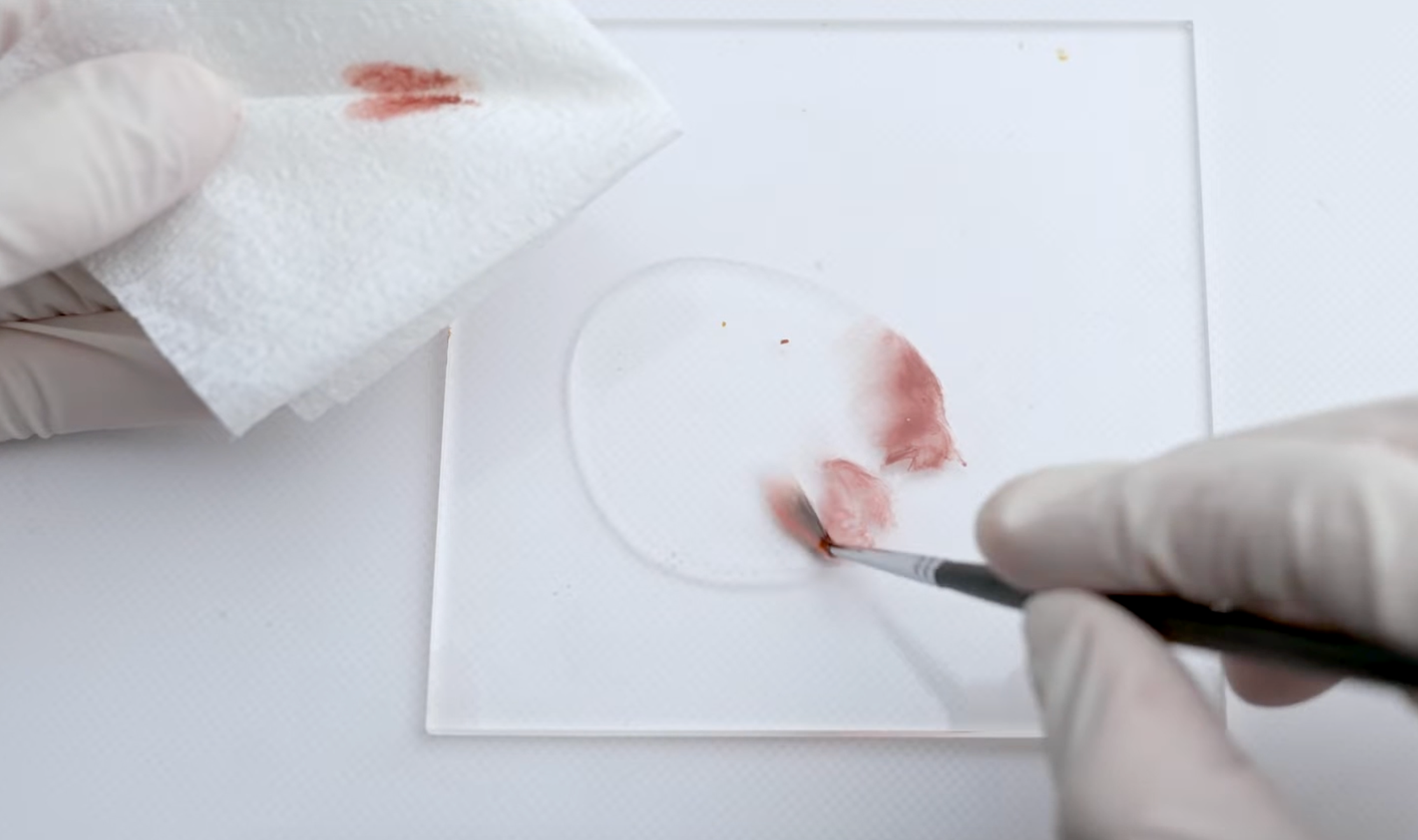

How to wash brushes

Wash brushes after use with vegetable oil such as rapeseed oil.

Dip the brush into the oil that has been put out on the acrylic plate and wipe it off with a tissue.

Repeat this process until there is almost no color on the tissue.

Finally, put the cap on and store the brush with a little oil remaining on it.

Otherwise, the brush tip may harden.

Finally, completely wipe off any oil remaining on the acrylic plate with ethanol.

If even a small amount of oil is left, it may mix with the oil and prevent the urushi from hardening next time.

1. Scrape off the sabi-urushi

After the sabi-urushi has hardened, scrape off it on the overhangs with a cutter to make the seams flat and even.

If the surface is large and difficult to smooth with a cutter, use a sandpaper to smooth the surface as much as possible.

Wipe off any dirt on the surface of the ceramics with an ethanol-soaked tissue as appropriate.

2. Coating the seams with "Bengara urushi"

Once the seams are flatten, coat the seams with "Bengara urushi".

Wipe the brush tip thoroughly with ethanol first before use.

It is recommended to apply the inside first because if you apply the outside first, you may touch the seam when applying the inside.

The purpose of this process is not to simply coat the seams, but to fill in the small dents by pouring bengara urushi into the seams to further flatten the surface.

Therefore, if the surface is rough like this, the coating is not sufficient.

Work as if you were "filling in the gaps with urushi" rather than "applying urushi".

Apply so that the surface is this smooth.

3. Wait few days to harden

When you have finished coating, leave it in the humid room and wait for a few days.

Also, keep the temperature around 25°C and the humidity around 70% because it will not harden if the temperature and humidity is too low.

On the other hand, too high a humidity of 80% or more is not good, as it may cause wrinkles when the urushi hardens.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

How to wash brushes

Wash brushes after use with vegetable oil such as rapeseed oil.

Dip the brush into the oil that has been put out on the acrylic plate and wipe it off with a tissue.

Repeat this process until there is almost no color on the tissue.

Finally, put the cap on and store the brush with a little oil remaining on it.

Otherwise, the brush tip may harden.

Finally, completely wipe off any oil remaining on the acrylic plate with ethanol.

If even a small amount of oil is left, it may mix with the oil and prevent the urushi from hardening next time.

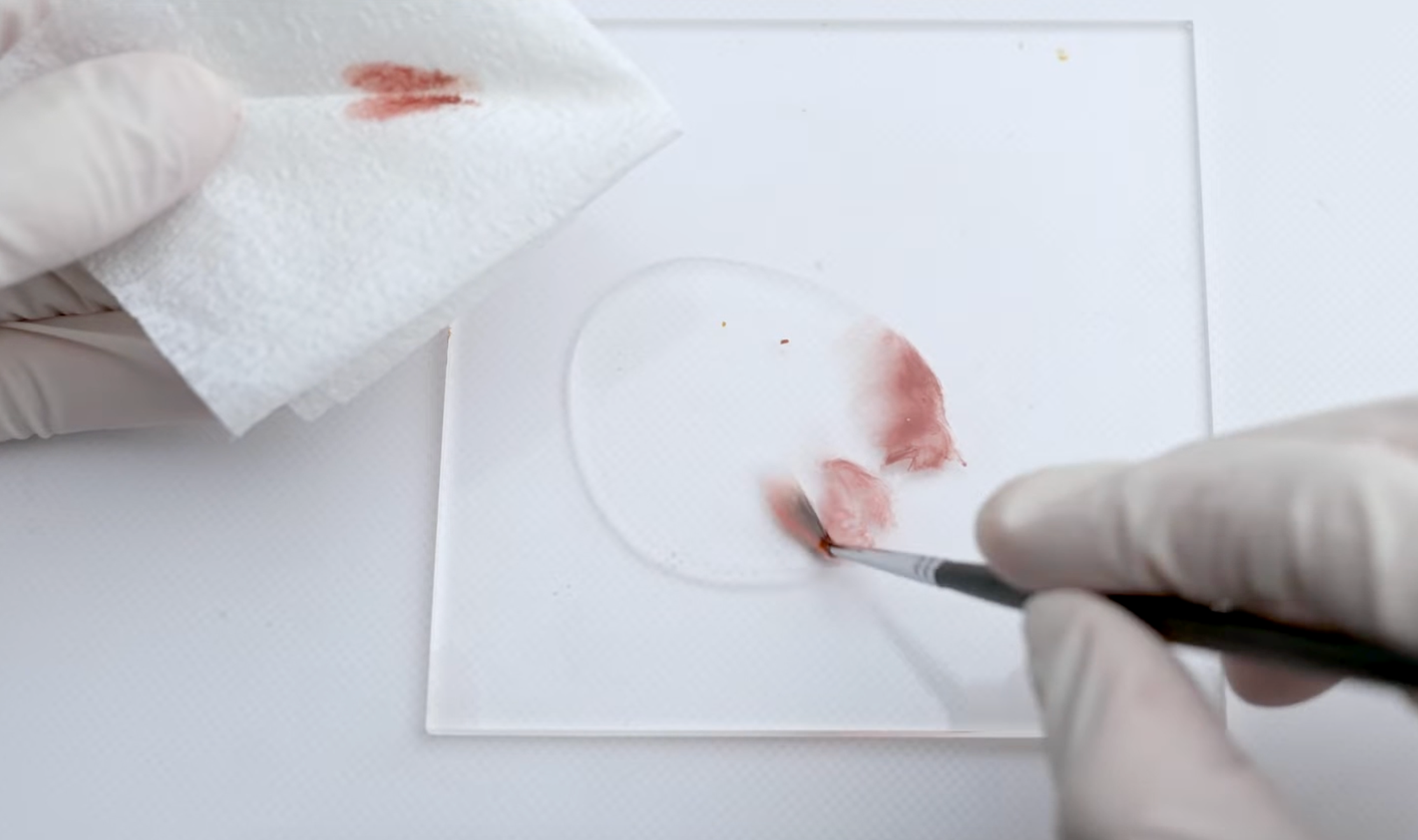

1. Polish the seams with an abrasive sheets

After the first coat of bengara urushi dries, polish the seams using soft abrasive sheets.

The polishing sheet is soft and fine-grained, so it will not scratch the glaze even if it is polished directly.

However, the gilding and painting may come off, so protect it with masking tape beforehand.

When the seams are flat enough that you can run your finger over them and not feel any bumps, wipe with ethanol.

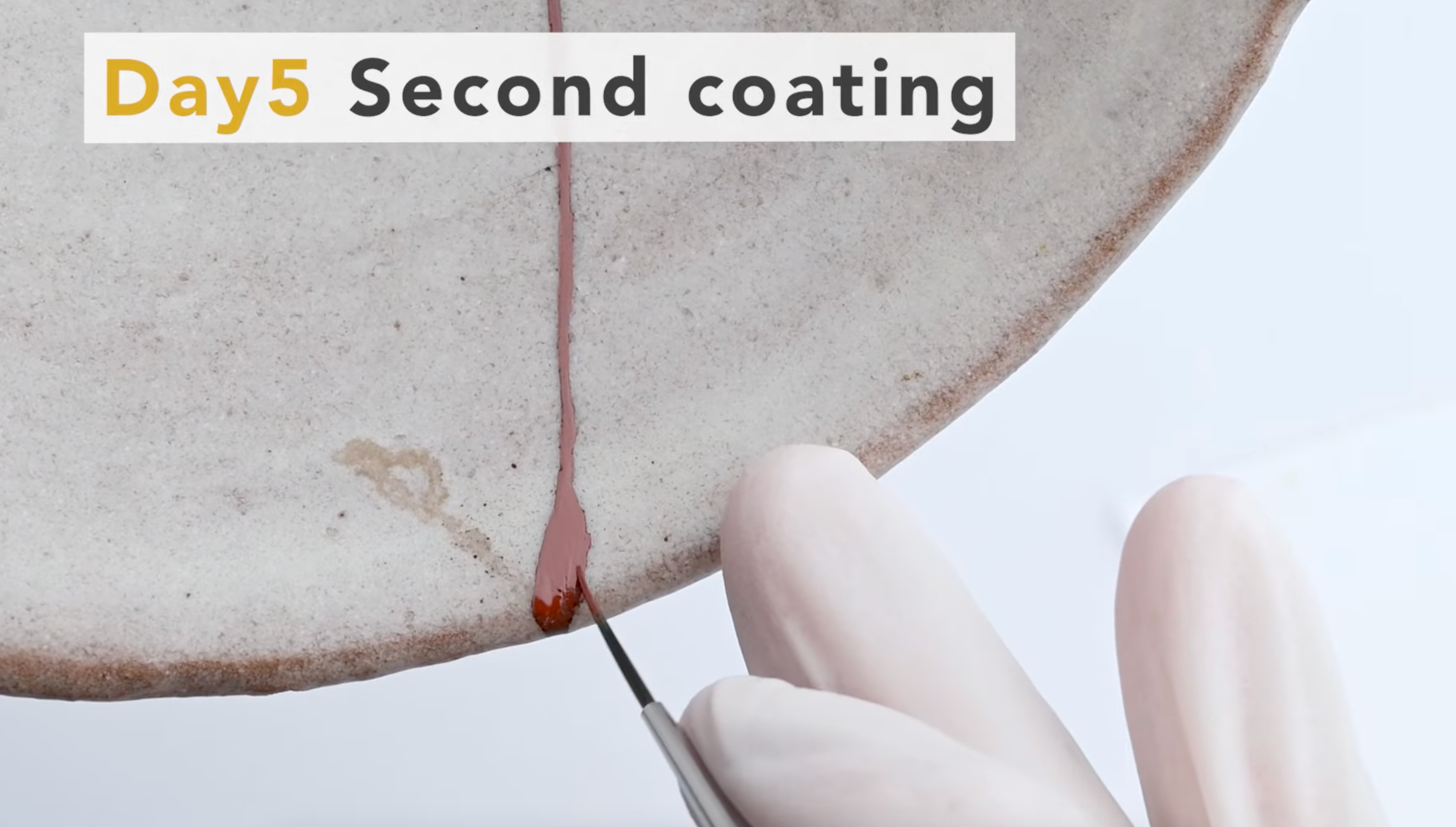

2. Coating with bengara urushi

Once polished, in many cases grooves and wrinkles still remain.

In such cases, coat the surface again using the same procedure as step 4.

Wipe the brush tip thoroughly with ethanol first before use.

When you have finished coating, leave it in the humid and warm place and wait for a few days.

- Tips

- In this procedure, the coating process has been applied twice, but basically the coating process is repeated until the seams are flat. Conversely, if the work is finished beautifully at the point of the first coat, the 2nd coat may not be applied.

How to wash brushes

Wash brushes after use with vegetable oil such as rapeseed oil.

Dip the brush into the oil that has been put out on the acrylic plate and wipe it off with a tissue.

Repeat this process until there is almost no color on the tissue.

Finally, put the cap on and store the brush with a little oil remaining on it.

Otherwise, the brush tip may harden.

Finally, completely wipe off any oil remaining on the acrylic plate with ethanol.

If even a small amount of oil is left, it may mix with the oil and prevent the urushi from hardening next time.

1. Polish the seams with an abrasive sheets

After the first coat of bengara urushi dries, polish the seams using soft abrasive sheets.

The polishing sheet is soft and fine-grained, so it will not scratch the glaze even if it is polished directly.

However, the gilding and painting may come off, so protect it with masking tape beforehand.

When the seams are flat enough that you can run your finger over them and not feel any bumps, wipe with ethanol.

2. Coating with bengara urushi

Once polished, in many cases grooves and wrinkles still remain.

In such cases, coat the surface again using the same procedure as step 4.

Wipe the brush tip thoroughly with ethanol first before use.

When you have finished coating, leave it in the humid and warm place and wait for a few days.

- Tips

- In this procedure, the coating process has been applied twice, but basically the coating process is repeated until the seams are flat. Conversely, if the work is finished beautifully at the point of the first coat, the 2nd coat may not be applied.

How to wash brushes

Wash brushes after use with vegetable oil such as rapeseed oil.

Dip the brush into the oil that has been put out on the acrylic plate and wipe it off with a tissue.

Repeat this process until there is almost no color on the tissue.

Finally, put the cap on and store the brush with a little oil remaining on it.

Otherwise, the brush tip may harden.

Finally, completely wipe off any oil remaining on the acrylic plate with ethanol.

If even a small amount of oil is left, it may mix with the oil and prevent the urushi from hardening next time.

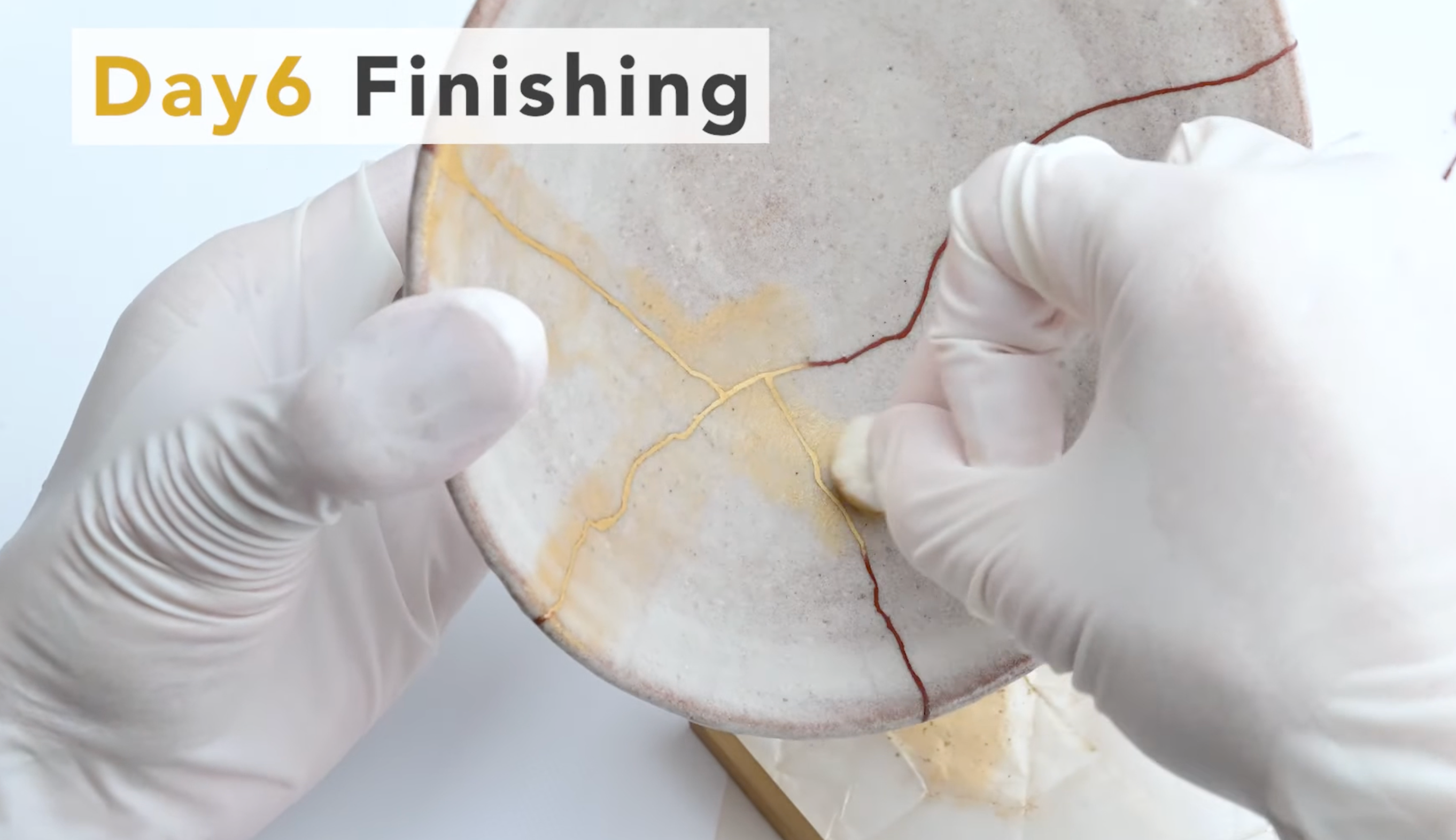

1. Polish the seams with an abrasive sheet

After the 2nd coat of bengara urushi dries, polish the seams using an abrasive sheet.

The polishing sheet is soft and fine-grained, so it will not scratch the glaze even if it is polished directly.

However, the painting may come off, so protect it with masking tape beforehand.

When the seams are flat enough that you can run your finger over them and not feel any bumps, wipe the whole thing down with ethanol.

2. Apply a thin coat of Bengara-urushi

Once the seams are in place, it is time to prepare for applying gold powder.

First, a "thin" layer of bengara-urushi is applied to the seams.

Be careful not to apply it too thickly, otherwise the gold powder will sink into the bengara urushi.

- Tips for applying thin coat

- Put a little bengara urushi on the brush tip.

- Move the brush slowly.

- Do not add more bengara urushi until the bengara urushi becomes faint.

If you add bengara urushi to the tip frequently, it will be applied too thickly.

3. Apply gold powder on the seams

After applying bengara-urushi, apply gold powder.

First, put generous amount of gold powder on a cotton ball.

Then move the cotton ball in small circles over the seams.

- Tips

- Be careful that the cotton itself does not touch urushi.

- Ideally, only the gold powder on the cotton should touch the urushi.

- The key is to apply gently and with as little force as possible.

After the entire surface has been applied with gold powder, add more gold powder on the cotton ball, and move the cotton ball around the seams to apply it in a spaceless way.

This will give it more luster.

When you have finished applying, leave it in the humid room and wait for a few days.

Also, keep the temperature around 25°C and the humidity around 70% because it will not harden if the temperature and humidity is too low.

On the other hand, too high a humidity of 80% or more is not good, as it may cause wrinkles when the urushi hardens.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

4. Completion

After one to two weeks in the urushi room, the bengara urushi hardens and the gold powder is fixed to the seams.

Wipe off the surface with a wet wipe to complete the process.

At this time, wipe with water, not ethanol.

Wiping with ethanol may remove even gold powder.

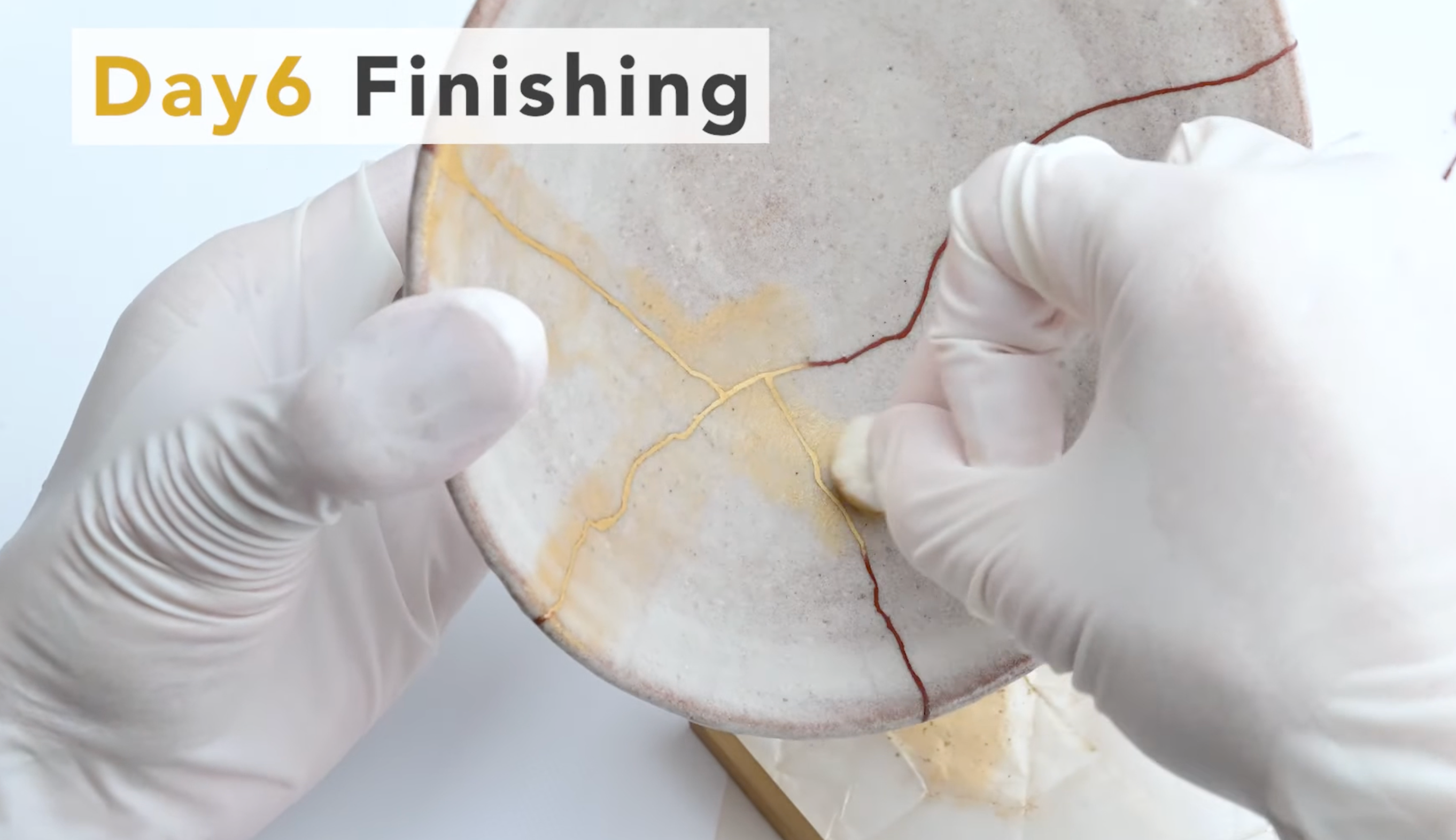

1. Polish the seams with an abrasive sheet

After the 2nd coat of bengara urushi dries, polish the seams using an abrasive sheet.

The polishing sheet is soft and fine-grained, so it will not scratch the glaze even if it is polished directly.

However, the painting may come off, so protect it with masking tape beforehand.

When the seams are flat enough that you can run your finger over them and not feel any bumps, wipe the whole thing down with ethanol.

2. Apply a thin coat of Bengara-urushi

Once the seams are in place, it is time to prepare for applying gold powder.

First, a "thin" layer of bengara-urushi is applied to the seams.

Be careful not to apply it too thickly, otherwise the gold powder will sink into the bengara urushi.

- Tips for applying thin coat

- Put a little bengara urushi on the brush tip.

- Move the brush slowly.

- Do not add more bengara urushi until the bengara urushi becomes faint.

If you add bengara urushi to the tip frequently, it will be applied too thickly.

3. Apply gold powder on the seams

After applying bengara-urushi, apply gold powder.

First, put generous amount of gold powder on a cotton ball.

Then move the cotton ball in small circles over the seams.

- Tips

- Be careful that the cotton itself does not touch urushi.

- Ideally, only the gold powder on the cotton should touch the urushi.

- The key is to apply gently and with as little force as possible.

After the entire surface has been applied with gold powder, add more gold powder on the cotton ball, and move the cotton ball around the seams to apply it in a spaceless way.

This will give it more luster.

When you have finished applying, leave it in the humid room and wait for a few days.

Also, keep the temperature around 25°C and the humidity around 70% because it will not harden if the temperature and humidity is too low.

On the other hand, too high a humidity of 80% or more is not good, as it may cause wrinkles when the urushi hardens.

- note

- One method is to place wet towels in cardboard boxes to maintain the right humidity for storage.

- The temperature should also be kept from getting cold by using air conditioning.

- In particular, urushi may not harden properly if the temperature falls below 20 degrees Celsius, so be careful to control both temperature and humidity after working on this and subsequent steps.

4. Completion

After one to two weeks in the urushi room, the bengara urushi hardens and the gold powder is fixed to the seams.

Wipe off the surface with a wet wipe to complete the process.

At this time, wipe with water, not ethanol.

Wiping with ethanol may remove even gold powder.

Basic Kit

Lesson 01: Broken

4 comments

Chimahaga

Hello Anne, I am sorry it has taken me so long to respond to your question, because I have not received notifications of comments for a long time.

It may be too late, but I will answer your question now as it will be helpful to others.

-——————-

Thank you so much for your purchase! We really appreciate it.

If your kintsugi kit includes Jinoko, Tonoko and Kokusowata, that means you have our Standard kit. In that case, please refer to the articles tagged “Standard kit” in the list of related content.

fx.) https://chimahaga.com/blogs/tutorials/lesson-04-broken-ceramics-repaired-with-advanced-kit

We understand this can be a bit confusing, so we’ll work on making the guidance clearer about which tutorials to follow for each kit type. Your feedback is extremely valuable to us.

Please don’t hesitate to reach out if you have any other questions! We’re always happy to help however we can. You can contact us anytime.

Thanks again for choosing our kintsugi products. We hope you have an amazing experience with your repairs!

Anne Kimpton

My kit contains Jinoko powder, Tonoko powder, and kokusowata powder. What are the English translations for these powders? Which one is wood powder for step 2?

Chimahaga

Hi May,

thanks for your comments!

If you followed our tutorial and repaired the pot, you may use it for eating and drinking.

However, never heat metals such as gold powder in a microwave oven, as they are likely to spark and pose a fire hazard.

Also, please do not use it in an oven or over an open flame, as it may be damaged if exposed to too high a temperature.

For other handling instructions, please check the article below.

https://chimahaga.com/blogs/journal/is-kintsugi-ware-dishwasher-safe

Wishing you a joyful kintsugi life!

May

Hi👋

It’s looks Amazing!

Can we use the pots usually after doing it? Can we eat/drink from this pot?

Can use in the microwave? Or an oven?

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.